Price of Stainless Steel Linear Vibrating Screen

Wednesday July-16 2025 15:53:28

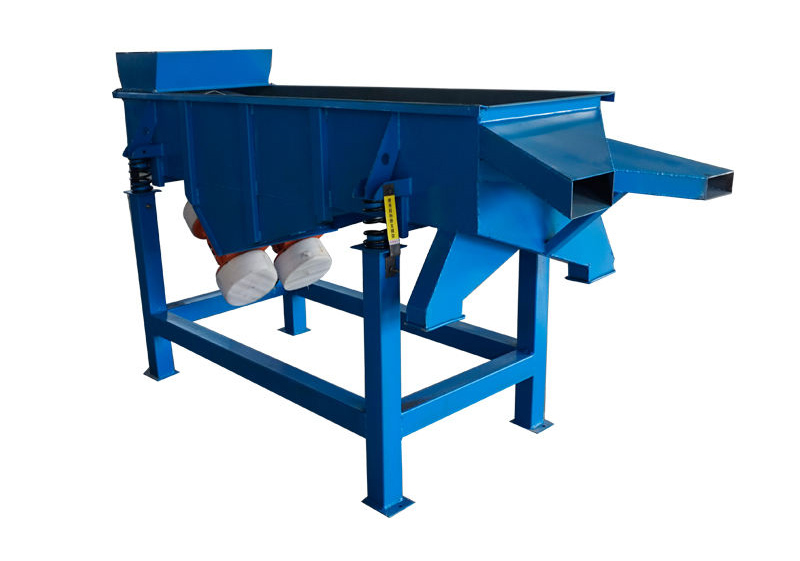

The Stainless Steel Linear Vibrating Screen is a device that achieves efficient material screening through a linear vibration trajectory. It can accurately separate solid particles of different sizes and is widely used in grading, impurity removal, and filtration processes for various materials. The equipment is made of 304/316 stainless steel with a finely polished surface, leaving no hygiene dead spots, making it suitable for industries with strict hygiene standards such as food, pharmaceuticals, and fine chemicals. Its procurement cost ranges from (650.00 to )8,000.00 per set depending on the model and configuration, with specific pricing influenced by a combination of factors.

What factors affect the price of Stainless Steel Linear Vibrating Screens?

Stainless Steel Linear Vibrating Screens, as important screening equipment in industrial production, have their prices affected by multiple factors. Differences in every link, from raw materials to production processes, and from product specifications to brand services, can lead to variations in the final price.

Material

Stainless Steel Linear Vibrating Screens mainly come in two options: 304 and 316 stainless steel. The key difference is that 316 stainless steel offers stronger corrosion resistance and higher temperature resistance than 304 stainless steel, but it is also more expensive. If the temperature and acidity of the materials you need to screen are moderate, it is recommended to choose 304 stainless steel.

Model Differences

Common models include DZSF515, DZSF520, DZSF525, DZSF1020, DZSF1025, and DZSF1030. The choice of model mainly depends on the screening output — the higher the output, the larger the required model, and the higher the price. For example, under the same material and number of screen layers, the price of a 1-layer DZSF-515 is approximately $650, while a 1-layer DZSF-520 is around $750.

| Model | DH-520 | DH-520 | DH-530 | DH-1020 | DH-1025 | DH-1030 |

| Dimension (mm) | 500×2000 | 500×2500 | 500×3000 | 1000×2000 | 1000×2500 | 1000×3000 |

| Material diameter (mm) | 0.074-20 | 0.074-20 | 0.074-20 | 0.074-40 | 0.074-40 | 0.074-40 |

| Shake frequency(time/min) | 960 | |||||

| Gradient | 1-7 | |||||

| Amplitude | 1-4.5 | |||||

| The layer number | 1-5 | |||||

| POWER (kw) | 2×(0.37-0.75) | 2×(0.37-0.75) | 2×(0.37-0.75) | 2×(0.75-1.1) | 2×(0.75-1.5) | 2×(0.75-1.5) |

Number of Screen Layers

The number of layers of Stainless Steel Linear Vibrating Screen screen surface can be up to 5 layers, a single layer is used for impurity removal, and multiple layers are used for sorting materials with different particle sizes. It is mainly selected according to the user's own screening purpose. The higher the number of layers, The higher the manufacturing cost, the more expensive the price will be. Under the same material and model, the price of Stainless Steel Linear Vibrating Screen will increase by 60~180$ for each layer.

Manufacturer and Brand Differences

Products from well-known brands and manufacturers usually have higher quality and after-sales service, and the prices will be relatively higher. Since its establishment 12 years ago, Dahan Machinery has a factory area of 10,000 square meters, providing screening solutions for food, medicine, chemical industry, metallurgy, building materials and other industries. Cooperative customers include Coca-Cola Company, Sundaban Industrial Complex Co., Ltd., etc. The company has ISO quality system certification and EU CE certification, and the product quality is guaranteed.

Customization

If special screen apertures, screen frame sizes or equipment structures need to be customized, the price will be adjusted based on the complexity of the customization.

How to choose a suitable Stainless Steel Linear Vibrating Screen based on price?

Choosing a Stainless Steel Linear Vibrating Screen based on price requires balancing your own needs and budget, avoiding blindly pursuing low prices that may lead to insufficient performance, or over-investing resulting in cost waste. The specific approaches are as follows:

Material Selection: If the materials do not require strong corrosion resistance or high-temperature resistance, choosing 304 stainless steel can save costs; if acid-alkaline or high-temperature environments are involved, although 316 stainless steel is more expensive, it can reduce long-term maintenance expenses.

Model Matching: Select the model according to actual output. For example, small workshops can meet their needs with DZSF515 (approximately $650) and do not need to pay extra for large-output models (such as DZSF1030).

Number of Screen Layers: Adopt a practical principle — choose basic models for single-layer impurity removal and add multiple layers for grading as needed, avoiding paying for unnecessary layers.

Brand Consideration: With a limited budget, you can choose regular manufacturers with high cost performance; for long-term use, well-known brands (such as Dahan Machinery), although slightly more expensive, offer better quality and after-sales service, which can reduce hidden costs.

Customization Needs: Evaluate the necessity of customization. Simple adjustments to screen aperture sizes involve a small price increase, while complex structural modifications require weighing input and output to ensure every budget corresponds to actual value.

Linear Vibrating Screen Price

| Model | Sieve size (mm) | Number of sieve layers | Mesh Size | Capacity (t/h) | Price | |

| Material Type | Carbon steel | Stainless steel | ||||

| DZSF515 | 500×1500 | 1~6 | 2-200 | 0.12-20 | $582-600 | $590-700 |

| DZSF520 | 500×2000 | 0.12-20 | $600-800 | $780-920 | ||

| DZSF525 | 500×2500 | 0.12-20 | $800-1300 | $1000-1500 | ||

| DZSF1020 | 100×2000 | 0.11-20 | $1500-2400 | $1900-2700 | ||

| DZSF1025 | 1000×2500 | 0.18-15 | $2500-3000 | $3000-3900 | ||

| DZSF1030 | 1000×2500 | 0.1-20 | $3000-3855 | $3800-4500 | ||

In summary, Stainless Steel Linear Vibrating Screens, with their high-quality 304/316 stainless steel materials and precise screening performance, play an important role in industries such as food and medicine. Their prices range from $650 to $8000, specifically affected by factors such as material, model, number of layers, brand, and customization needs. When choosing, you can find a cost-effective device by combining your own production needs and budget. For users with special production scenarios or material characteristics, our factory can specifically solve screening problems and provide professional customization plans to make the equipment more suitable for actual production needs.