What is Food Grade Vibro Sifter?

Wednesday July-16 2025 14:03:02

The difference between Food Grade Vibro Sifter and ordinary vibrating screen is mainly reflected in the material and application. Food Grade Vibro Sifter is mainly used in the screening of raw materials, semi-finished granules, powder and even liquid materials in the food industry.

How is Food Grade Vibro Sifter classified by material?

Food Grade Vibro Sifter is categorized into two main types based on material: 304 stainless steel and 316L stainless steel, each with distinct properties and applications.

Compared with 304 stainless steel vibrating screen, 316L stainless steel contains 2~3% molybdenum element, which has stronger acid and alkali corrosion resistance and temperature resistance, and can withstand high temperature of 700°C. It should be below 400°C. In addition, 304 stainless steel can be called food-grade stainless steel, and 316 stainless steel can be called pharmaceutical-grade stainless steel. Under the same weight, the price of 316 stainless steel will be more expensive.

What is the working principle of Food Grade Vibro Sifter?

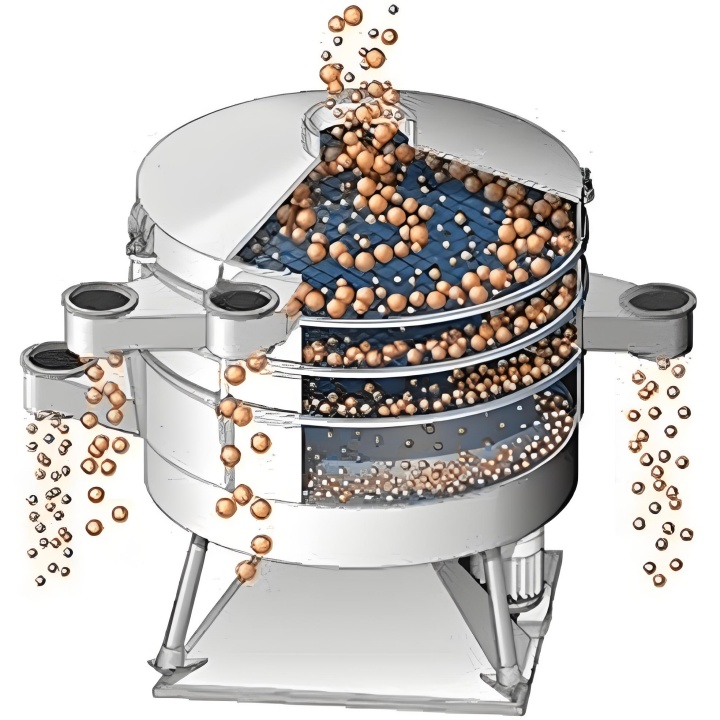

Food Grade Vibro Sifter operates through mechanical vibration to achieve material separation and impurity removal, with a design focused on efficiency and hygiene.

It uses a vibration motor to generate centrifugal force, making materials jump and spread evenly on the screen surface. Through multi-layer screen meshes of different apertures, materials are separated into various particle sizes, while impurities are retained on the top layer, completing the screening process.

What are the core advantages of Food Grade Vibro Sifter?

Food Grade Vibro Sifter boasts advantages in material safety, corrosion resistance, and functional design, making it ideal for high-hygiene and corrosive environments.

Its corrosion-resistant, clean, and rust-free materials ensure safety in food and pharmaceutical use. The built-in food-grade silicone sealing ring and screen-clearing bouncing ball enhance sealing and prevent mesh blockage, ensuring stable operation.

Technical parameters of food grade vibro sifter

| Model | Diameter (mm) | Feeding Size (mm) | Frequency (RPM) | Layers | Power (kw) | Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

What are the application scenarios of Food Grade Vibro Sifter?

Food Grade Vibro Sifter is widely used in industries requiring strict hygiene and corrosion resistance, handling various material states for screening and impurity removal.

It is usually used in food and pharmaceutical industries to complete screening and impurity removal, including but not limited to materials in the state of granules, powders, and liquids, such as: Soybean, soybean milk, cinnamon powder, Chinese herbal medicine, almond, corn, fruit juice, starch, etc. It can also be used in chemical or environmental protection fields to screen some acid-base corrosive materials.

Food Grade Vibro Sifter can be made of all stainless steel or only the material contact part is made of stainless steel. According to different requirements, different screens can be designed with 1~5 layers to remove impurities or classify materials with 2~6 particle sizes. The built-in silicone sealing ring for food and the bouncing ball for clearing the screen have good sealing performance without material leakage and can also clean the blocked mesh in time. The screening output is 100~3300kg/h.