How do I choose a Rotary vibrating screen?

Monday August-04 2025 16:26:51

Rotary vibrating screen undertakes the important task of separation and size determination of particles in the production link, and is usually used in the initial processing and final packaging stages of products.

Customers often ask which rotary vibrating screen is better? Different models meet different needs. We need to conduct a comprehensive analysis of parameters such as material, screening mesh, output, etc. to better choose the right model. So how do I choose a rotary vibrating screen? The following is a detailed introduction for your reference:

Production demand

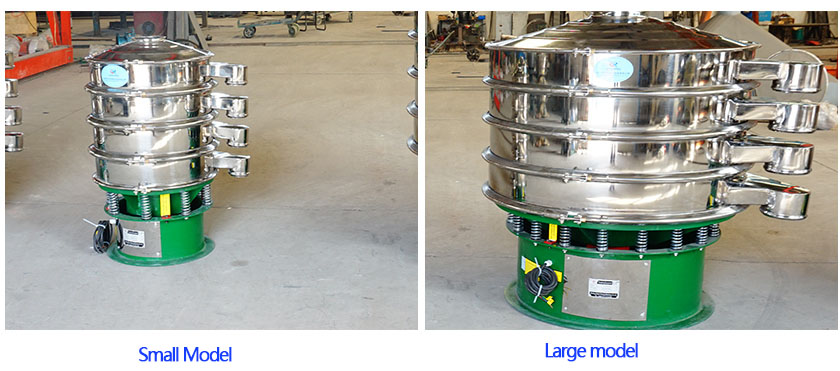

The screening output determines the choice of model. For users with small output, we will recommend small-sized Rotary vibrating screens such as 400mm and 600mm. For users with higher output requirements, we generally recommend users to choose large-sized Rotary vibrating screens such as 1500mm, 1800m, and 2000mm.

| Model | Power(kw) | Sieve diameter(mm) | Layers | Granularity(mm) | Voltage(v) | RMP(r/min) | Capacity(kg/h) |

| DH-400 | 0.18 | 350 | 1-4 | <10 | 380 | 1440 | 100 |

| DH-600 | 0.25 | 550 | 1-4 | <10 | 380 | 1440 | 500 |

| DH-800 | 0.55 | 750 | 1-4 | <10 | 380 | 1440 | 800 |

| DH-1000 | 0.75 | 920 | 1-4 | <10 | 380 | 1440 | 1400 |

| DH-1200 | 1.1 | 1120 | 1-4 | <10 | 380 | 1440 | 2100 |

| DH-1500 | 1.5 | 1420 | 1-4 | <10 | 380 | 1440 | 2600 |

| DH-1800 | 2.2 | 1720 | 1-4 | <10 | 380 | 1440 | 3300 |

Material condition - type, particle size and classification

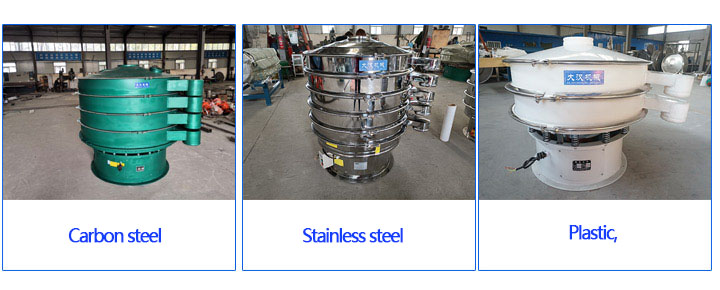

A. The type of material determines the material of the Rotary vibrating screen:

Different materials require different types of rotary vibrating screens. To meet our customers' needs, Dahan Machinery designs rotary vibrating screens in a variety of materials, each suitable for a variety of industries.

All-carbon steel rotary vibrating screens are low-cost and suitable for screening and filtering general materials.

All-stainless steel rotary vibrating screens, constructed from 304/316L, are suitable for foods, pharmaceuticals, and other materials with high hygienic standards or high corrosiveness, such as flour, condiments, sugar, sesame seeds, soybeans, traditional Chinese medicine powder, soy milk, juice, and soy sauce.

Plastic rotary vibrating screens are suitable for processing strongly acidic and alkaline powders, granules, and slurries, such as resin powder, fluorescent powder, spray paint, and coatings.

B. The particle size distribution of the material determines the selection of the mesh number of the screen:

Rotary vibrating screen mesh can be from 2 mesh to 500 mesh, according to the particle size that needs to be screened, select different mesh mesh to screen out the materials that meet the requirements.

| Material | Screen (mesh/inch) | Processing capacity (kg/hour) |

| Milk powder | 16.2 | 2000 |

| Sugar | 4.2 | 5000 |

| Salt | 30/80 | 5000 |

| Traditional Chinese Medicine Pesticide | 80/100/150 | 1400 |

| Traditional Chinese Medicine Powder | 80 | 550 |

| Electronic Jade Powder Resin DV | 40/60/80 | 1000 |

| Grinding Powder | 40/60/250 | 1200 |

| Pigment Powder | 20 | 4000 |

| Graphite | 16/40/80 | 1400 |

| Iron Powder | 60/80/120 | 2500 |

| Copper Powder | 80 | 2000 |

| Copper Powder | 40/65/200 | 2000 |

| Aluminum Silver Powder | 60 | 1500 |

| Starch | 80 | 1200 |

| Activated Carbon | 40/60 | 1000 |

| Paint | 100 | 7500 |

| Carborundum | 60 | 300 |

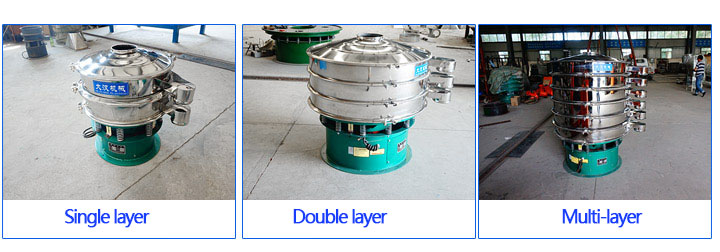

C. Material classification requirements determine the number of screen layers:

Rotary vibrating screens are available with 1-5 layers, capable of simultaneously grading 2-6 different particle sizes. Single-layer screens are used for removing impurities, while multi-layer screens are used for grading large and small particles. Customers can choose the number of layers based on the number of materials they wish to screen. For less demanding requirements, a lower number of layers can be chosen to save costs.

When choosing a Rotary vibrating screen, you must conduct a comprehensive analysis based on your material properties, screening purpose, application scenarios and other parameters to select the most cost-effective equipment. For more information, please send an email to sale@xxdahan.com