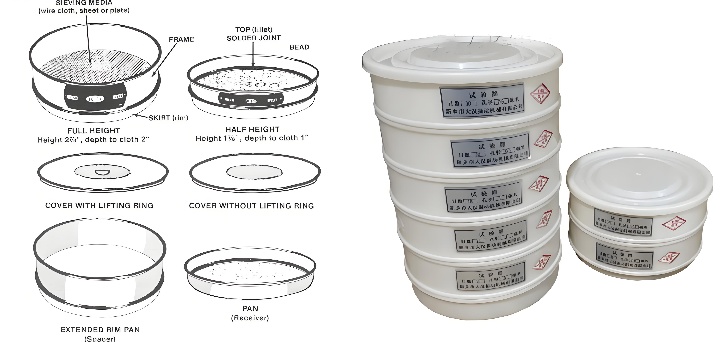

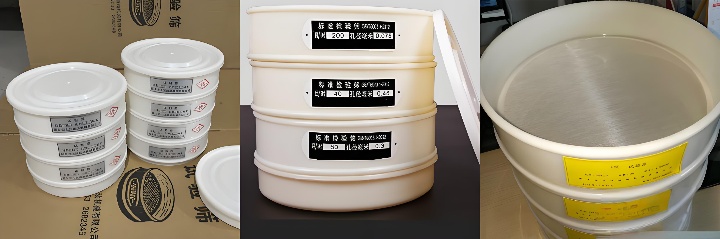

Nylon plastic test sieve for laboratory use

Saturday July-12 2025 12:43:42

What is a nylon plastic test sieve for laboratory use?

Nylon plastic test sieve for laboratory use is a common tool for particle size analysis and screening of granular powder materials in the laboratory. It is mainly used for screening and separation of solid samples. Its main body consists of a plastic frame and a nylon (polyamide) screen. The nylon screen has certain chemical resistance and elasticity, and the screening mesh range is wide, usually between 20-500 mesh where a higher mesh number indicates a smaller sieve aperture size. This range corresponds to an aperture of about 850 microns to 25 microns, allowing for the accurate separation of materials based on different particle sizes.

What are the differences between nylon plastic test sieve for laboratory use and laboratory stainless steel test sieve?

Laboratory nylon plastic test sieves and stainless steel test sieves differ significantly in their material composition, which in turn affects their basic properties. The former uses nylon for the screen and plastic for the frame, while the latter is entirely made of stainless steel.

Material:

Nylon plastic test sieve for laboratory use: The screen is made of nylon (polyamide) material, and the frame is usually plastic (such as polypropylene).

Laboratory stainless steel test sieve: Both the screen and the frame are made of stainless steel. Common stainless steel models are 304 or 316L, with different corrosion resistance.

Features:

|

Features |

Nylon plastic test sieve for laboratory use |

Stainless steel test sieve for laboratory use |

|

Aperture range |

20μm-4.75mm |

20μm-125mm (customizable ultra-micropores) |

|

Chemical resistance |

Has a certain tolerance to certain chemicals |

Excellent chemical corrosion resistance, acid resistance, alkali resistance, organic solvent resistance, wider application range |

|

Temperature resistance |

Relatively low temperature resistance, may deform at high temperature |

Good high temperature resistance |

|

Strength and wear resistance |

Strength and wear resistance are not as good as stainless steel |

High strength, wear resistance, not easy to deform and damage |

|

Conductivity |

Non-conductive |

Conductive |

|

Elasticity |

Has a certain elasticity, Suitable for some special applications |

relatively small flexibility |

|

Cost |

usually low cost, an economical choice |

relatively high cost |

|

Applicability |

more suitable for experiments that interfere with metal ions, as well as one-time or short-term use scenarios |

wide range of applications, especially for experiments that require high precision, high cleanliness, and corrosion resistance |

How does the nylon plastic test sieve for laboratory use work?

The laboratory nylon plastic test sieve relies on particle size differences to complete material separation, with multiple mechanisms working together to ensure efficiency.

Place the material to be screened on the nylon screen of the test sieve, and the material particles will fall naturally under the action of gravity. Smaller Small particles can fall through the sieve holes to the lower layer, while larger particles are intercepted by the sieve and remain above the sieve, thereby achieving the initial separation of particles of different sizes.

Through vibration, the material is made to jump and roll on the sieve, increasing the chance of particles contacting the sieve holes. Vibration can also prevent material particles from accumulating and clogging at the sieve holes, allowing smaller particles to pass through the sieve holes more smoothly. For some irregularly shaped particles, vibration helps them pass through the sieve holes in a suitable posture, further improving the accuracy of screening.

What are the advantages of nylon plastic test sieve for laboratory use?

Laboratory nylon plastic test sieves offer several unique advantages that make them suitable for specific laboratory scenarios. These advantages stem from the properties of nylon material, such as chemical inertness and smooth surface, which address common issues in material screening.

Avoid material contamination: Traditional metal sieves may have If the nylon material itself has excellent chemical inertness, it is not easy to react with most chemicals and will not rust, which fundamentally avoids material contamination caused by the material of the screen itself.

Reduce material residue and improve separation efficiency: The surface of the metal screen is relatively rough and it is easy to absorb fine material particles, resulting in incomplete screening. The surface of nylon wire is smooth and has a small friction coefficient. Material particles are not easy to adhere to the screen, thereby reducing material residue. The smooth surface also makes the screen more Easy to clean and avoid cross contamination.

Dealing with static electricity problems: When screening dry powdered materials, static electricity is easily generated due to friction, causing material particles to be adsorbed on the metal screen, blocking the mesh and even affecting the experimental results. Nylon materials have poor conductivity, which can reduce the generation and accumulation of static electricity to a certain extent, thereby reducing the clogging problem caused by static adsorption of materials.

Adapting to the corrosiveness of special materials: Some laboratory materials are highly corrosive, which will corrode the metal screen, shorten its service life, and may affect the experimental results. The nylon plastic test sieve for laboratory use has good acid resistance, alkali resistance and organic solvent resistance, and can Adapts to the screening needs of various corrosive materials.

In which scenarios is the nylon plastic test sieve for laboratory use commonly applied?

Laboratory nylon plastic test sieves find extensive use in various laboratory activities due to their unique properties. They are particularly valued in tasks requiring precise particle separation and compatibility with specific materials.

Particle size analysis of powders and particles: Nylon sieve has uniform mesh size. The nylon plastic test sieve for laboratory use can accurately separate powders and particles of different particle sizes. Nylon material usually has certain antistatic and low hygroscopicity, which helps to reduce the adhesion of powders and the clogging of sieve holes, especially when dealing with fine or hygroscopic particles.

Filtration of liquids and suspended matter: Nylon sieve can effectively filter solid impurities and suspended matter in liquids, such as removing undissolved particles when preparing solutions or culture media. In biological laboratories , nylon mesh with a specific aperture can be used to separate cells, microorganisms or other biological particles of different sizes. Nylon mesh can be used to remove large particles from samples before performing certain analytical tests, such as liquid chromatography or mass spectrometry.

Teaching and scientific research: Nylon mesh can be used to demonstrate the separation process of materials of different particle sizes. In materials science research, nylon mesh can be used to prepare experimental samples of specific particle sizes. Nylon plastic test sieves for laboratory use can be used to separate particles of specific sizes in water or soil samples for environmental analysis.

Nylon plastic test sieve for laboratory use are suitable for laboratory sieving needs with medium and low precision and non-extreme environments. When selecting a model, it is necessary to give priority to matching the sieve hole standard and the material's temperature/corrosion resistance, combined with Dahan's supplier's customization capabilities and after-sales service to ensure the accuracy of the experimental results and ease of operation. For high-load or extreme conditions, it is recommended to add a stainless steel sieve as an alternative.