Soil sieve vs sand sieve

Thursday July-17 2025 16:38:28

Both Soil sieve and sand sieve are professional tools in the field of particle classification. They share the same core principle — both achieve material separation by particle size through apertures of different specifications, and both have clear classification standards and applicable scenarios. They are widely used in geological exploration, construction engineering, laboratory analysis and other fields, providing key support for the precise classification of material particles.

Soil sieve is a professional tool for analyzing soil particle size distribution. It classifies and screens soil according to different physical properties of soil (such as particles of different sizes like sand, silt, and clay). Soil is usually composed of coarse graded stones to fine soil particles, with particle sizes ranging from a few millimeters to a few microns. Common sieving methods include 2 mm (separating graded stones from sand), 0.25 mm (boundary between sand and silt), 0.05 mm (boundary between silt and clay), etc. The recommended mesh sizes are 10 mesh, 60 mesh, 200 mesh, etc., which are suitable for fine laboratory analysis.

Sand sieve is a tool for screening sand materials. It classifies sand according to its characteristics (such as relatively uniform particle size, mainly medium and coarse particles). The particle size of sand is usually between 0.075 mm and 4.75 mm, which is a coarse particle with good wear resistance and fluidity. Common apertures of sand sieves are 4.75 mm, 2.36 mm, 1.18 mm, 0.6 mm, etc. The recommended mesh sizes are 4 mesh, 8 mesh, 16 mesh, 30 mesh, etc., which are suitable for separating coarse sand, medium sand and fine sand.

Differences between soil sieve and sand sieve

Soil sieves are often used for standard screening in laboratories, such as soil particle grading tests, which require high precision and a wide screening range, and are suitable for grading different particle sizes; sand sieves are mainly used for rapid grading of sand and gravel on engineering sites or production lines. The screens are coarse and focus on efficiency and durability.

|

Comparison point |

Soil sieve |

Sand sieve |

|

Image |

|

|

|

Main application |

Soil particle classification, experimental analysis |

Sand classification, construction material processing |

|

Common aperture range |

0.075mm to 4.75mm |

Usually between 0.3mm and 5mm |

|

Common mesh size |

2 mesh to 200 mesh (depending on experimental requirements) |

4 mesh to 60 mesh (coarse particle size classification) |

|

Usage accuracy |

High-precision experimental requirements |

Coarse screening or impurity removal |

|

Hierarchical structure |

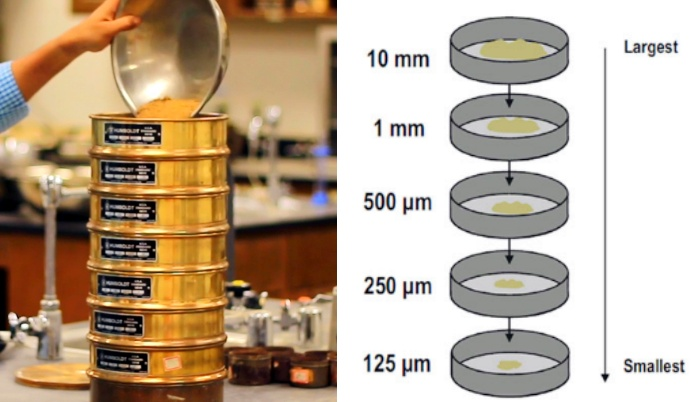

Multi-layer sieve (such as a standard sieve with a diameter of 200mm) |

One or two Most of them are layer grading sieves |

|

Application fields |

Agriculture, geology, environment, laboratory |

construction, sand and gravel plant, concrete mixing, etc. |

Sieve hole size of soil sieve and sand sieve

Soil sieve: The coarse sieve commonly used in geotechnical tests is generally round hole, with a hole diameter of 100mm, 80mm, 60mm, 40mm, 20mm, 10mm, 5mm, 2mm, etc.; the fine sieve is generally square hole, with an equivalent hole diameter of 2.0mm, 1.0mm, 0.5mm, 0.25mm, 0.10mm, 0.075mm.

Sand sieve: Common sand sieve aperture specifications include 0.075mm, 0.15mm, 0.3mm, 0.6mm, 1.18mm, 2.36mm, 4.75mm, 9.5mm, etc., mainly concentrated in the finer particle range

Recommended mesh size of soil sieve and sand sieve

The standard sieve combination used for soil grading test is usually: 4.75mm, 2.00mm, 0.425mm, 0.075mm, and sometimes more sieves are used for fine analysis.

|

Screen mesh number |

aperture (mm) |

instructions |

|

4 mesh |

4.75mm |

particles larger than coarse sand |

|

10 mesh |

2.00mm |

coarse sand |

|

20 mesh |

0.85mm |

medium sand |

|

40 mesh |

0.425mm |

fine sand |

|

60 mesh |

0.25mm |

ultra-fine sand |

|

100 mesh |

0.15mm |

powder |

|

200 mesh |

0.075mm |

boundary between powder and clay |

Recommended combination: The screen combinations commonly used for construction sand grade analysis are: 4.75mm, 2.36mm, 1.18mm, 0.6mm, 0.3mm, 0.15mm.

|

Screen mesh number |

aperture (mm) |

instructions |

|

4 mesh |

4.75mm |

coarse sand, gravel screening |

|

8 mesh |

2.36mm |

medium sand and coarse sand boundary |

|

16 mesh |

1.18mm |

medium sand |

|

30 mesh |

0.6mm |

fine sand |

|

50 mesh |

0.3mm |

ultra-fine sand |

|

60 mesh |

0.25mm |

removal of fine particles or impurities |

What are the uses of soil sieves and sand sieves?

Soil sieves are mainly used for grading, screening, analysis, and testing of soil samples in various laboratories to determine the composition ratio of particles of different sizes in the soil, understand the physical properties of the soil, such as particle grading, porosity, etc., and can also be used for soil separation, purification, and removal of impurities in the soil. They are widely used in agriculture, geology, environmental science and other fields.

Sand screens are usually used to screen sand in the construction industry to ensure that the particle size of the sand meets the standards for construction sand, such as for concrete mixing, wall building, plastering and other construction links; they are also used in sand fields, mines and other places to grade and screen sand particles, and separate sand of different particle sizes to meet the needs of different uses, such as glass making, casting, etc.

Although both Soil sieve and sand sieve are used to screen particulate matter, there are differences in the size of the sieve holes and application scenarios. Soil screens are mainly used for particle size analysis of soil samples to distinguish soil particles of different sizes, such as sand, silt and clay. This is very important for understanding soil texture, assessing soil fertility, conducting agronomic research, and environmental monitoring. Sand screens are mainly used to screen sand to remove impurities in sand or to grade sand by particle size.

Our factory's soil sieves and sand sieves deliver outstanding performance advantages: Soil sieves cover the full aperture range from 100mm to 0.075mm (featuring round holes for coarse sieves and square holes for fine sieves), achieving laboratory-grade precision at 200-mesh (0.075mm) with multi-layer 200mm standard sieves tailored for detailed laboratory analysis; sand sieves span apertures from 0.075mm to 9.5mm, offering complete specifications from 4-mesh (4.75mm) to 60-mesh (0.25mm) to meet grading requirements from coarse to ultra-fine sand. Both product lines utilize high-wear-resistant materials suitable for diverse sectors including agriculture and construction, and we support customization of aperture sizes, mesh counts, and sieve layer structures—contact us to obtain your tailored solution.