The difference between ultrasonic test sieve and slap sieve

Thursday July-17 2025 17:34:41

Ultrasonic test sieve and slap sieve are both equipment used for particle size analysis of materials such as powders and particles, but they have significant differences in working principle, scope of application and effect.

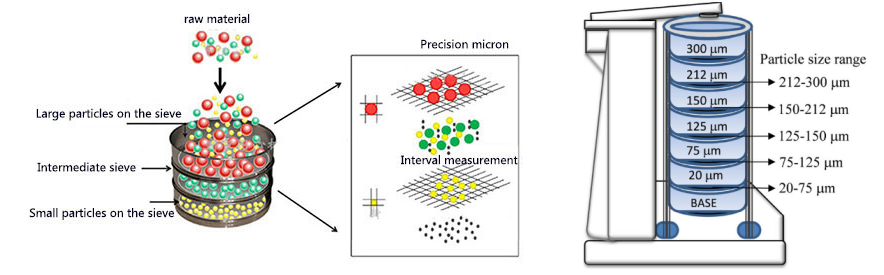

Ultrasonic test sieve uses high-frequency ultrasonic vibration to eliminate agglomeration and blockage, suitable for 2-200 mesh (0.075-4.75mm) ultra-fine materials like pharmaceutical powders, with aperture error ≤±0.3%.

Slap sieve relies on mechanical slapping, ideal for 4-60 mesh (0.25-4.75mm) medium-coarse particles such as construction sand, featuring 30-50 slaps/min for high efficiency but lower precision on fine powders.

Differences in scope of application

Ultrasonic test sieve: Suitable for fine screening of ultrafine powders (such as above 200 mesh), especially suitable for materials that are easy to agglomerate, light in specific gravity, strong in electrostatic properties, and easy to block the net, such as silicon powder, metal powder, drug powder, ceramic powder, etc. Slap screens are commonly used for dry particle screening in industries such as geology, metallurgy, cement, and construction. They are suitable for granular materials with a particle size greater than 75μm, such as sand, soil, ore, and grain.

Slap sieve: Commonly used for dry particle screening in industries such as geology, metallurgy, cement, and construction. They are suitable for granular materials with a particle size greater than 75μm, such as sand, soil, ore, and grain. They are also applicable to scenarios requiring rapid classification of medium-coarse particles (4-60 mesh) like construction aggregates and mineral raw materials.

Differences in working principles

The ultrasonic test sieve uses ultrasonic vibration to assist the screening process. It adds a high-frequency, low-amplitude ultrasonic vibration system to the traditional mechanical screening to make the screen produce additional vibrations. This vibration helps to destroy the adhesion between fine particles and the screen, thereby improving the screening efficiency and accuracy. It is particularly suitable for the screening of fine powders.

The slap screen works by mechanical slapping. It drives the eccentric wheel to rotate through a motor, so that the screen body moves up and down or forward and backward, and sometimes accompanied by a slapping action to help the material pass through the screen. This method is more suitable for the screening of coarse particle materials, which can effectively disperse the materials, reduce material accumulation, and ensure screening efficiency.

Differences in application scenarios

The main difference between ultrasonic test sieves and slap screens in application scenarios lies in the characteristics of the materials being processed and the screening accuracy requirements. Ultrasonic test sieves rely on high-frequency micro-amplitude vibrations, which are particularly suitable for the precision screening of ultrafine powders (such as medicines, nanomaterials, battery powders, etc.). They can effectively solve the problems of electrostatic agglomeration and clogging of micron-sized particles (especially <20μm), and are suitable for high-precision laboratories or industries with strict requirements on screening efficiency.

The slap screen relies on mechanical slapping and gravity, and is more suitable for medium-batch screening of conventional particles (such as grain, building materials, ores, etc.), especially for materials with high hardness, large particle size (20μm~25mm) or slight adhesion, which is more common in routine quality inspections in the fields of food, mining and chemical industry. If the sample is fragile, needs gentle treatment or screening of ultrafine powders, ultrasonic sieves are a better choice; if cost-effectiveness is pursued and ordinary particles are processed, slap screens are more practical.

Significant difference in screening effect

There is a significant difference in screening effect between ultrasonic test sieves and slap screens. The ultrasonic test sieve superimposes high-frequency ultrasonic vibration on the sieve, causing the sieve to produce a slight, high-frequency longitudinal vibration, effectively preventing fine powder from blocking the sieve and adhering, greatly improving the screening accuracy and efficiency. It is especially suitable for ultrafine powders with a particle size of more than 200 meshes. The screening process is more uniform and stable, and more accurate particle size distribution data can be obtained.

The slap screen mainly relies on the combined action of mechanical slapping and horizontal rotation to achieve screening. The screening action is more intense and is suitable for coarse particles or materials with higher density. However, for samples with smaller sieve holes and finer materials, problems such as clogging, skipping, and uneven stratification are prone to occur during the screening process, and the accuracy and grading effect are limited. Therefore, the ultrasonic test sieve has a better screening effect when processing high-fineness powders, while the slap screen is suitable for rapid screening and conventional particle size distribution analysis of medium-sized materials.

Comparison table of the difference between ultrasonic test sieve and slap screen

|

Comparison items |

ultrasonic test sieve |

slap screen |

|

Screening method |

high-frequency ultrasonic vibration |

mechanical slapping + horizontal rotation |

|

Applicable particle size |

ultrafine powder (below 20μm) |

medium-coarse particles (>75μm) |

|

Screening speed |

fast, screening is completed within a few minutes |

slow, generally takes 10 to 15 minutes |

|

Screening accuracy |

high, up to 500 mesh or more |

medium, commonly used within 200 mesh |

|

Anti-blocking net performance |

strong |

weak |

|

Application areas |

precision screening, laboratory ultrafine powder |

conventional particle size analysis of soil, stone, etc. |

Ultrasonic test sieve is more suitable for screening of fine powders; while slap screen is more suitable for coarse particle materials. The former relies on ultrasonic vibration to assist screening, while the latter achieves material separation through mechanical slapping. Ultrasonic test sieves are outstanding in anti-blocking nets and improving screening accuracy; slap screens show good dispersion effects when processing coarse particle materials. The selection of screening equipment should be based on specific screening needs, material characteristics, budget and other factors.

Solution

To meet diverse screening needs, we provide targeted solutions based on material characteristics: For ultrafine powders (below 20μm) with agglomeration or electrostatic issues (such as pharmaceutical powders, nanomaterials), the ultrasonic test sieve is recommended to ensure high precision (up to 500 mesh) and anti-clogging performance. For medium-coarse particles (>75μm) like sand, ore, and grain, the slap screen offers efficient classification with cost-effectiveness, suitable for industrial batch processing. We also offer customized services, including adjusting sieve mesh specifications (2-500 mesh), optimizing vibration parameters, and designing multi-layer sieve combinations, to tailor solutions for specific scenarios in laboratories, mines, construction, and other fields. Contact us for personalized screening plans.

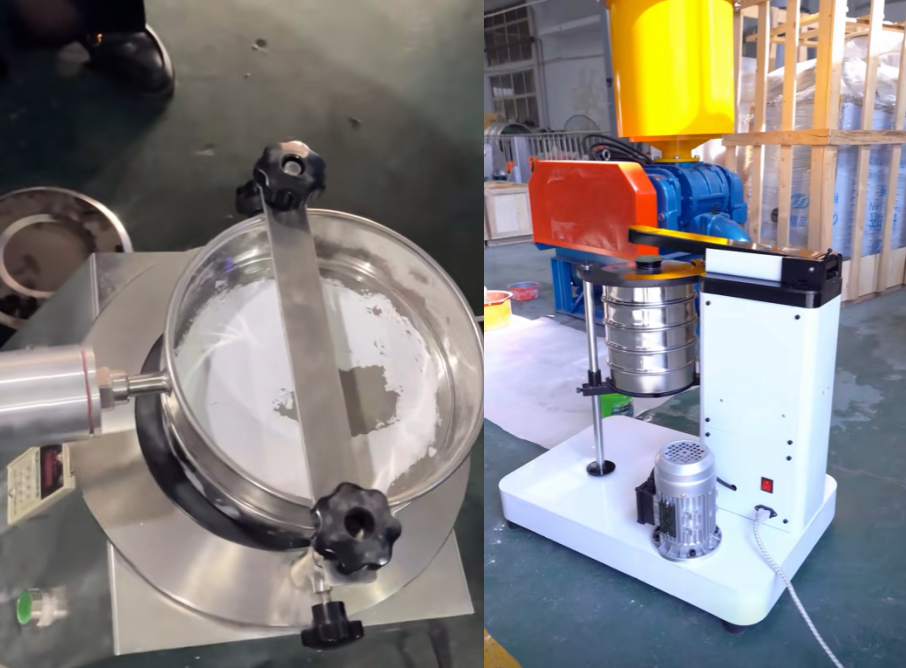

Ultrasonic test sieve used on site

Slap sieve used on site