What is Vibratory Sieve used for?

Wednesday August-13 2025 16:30:02

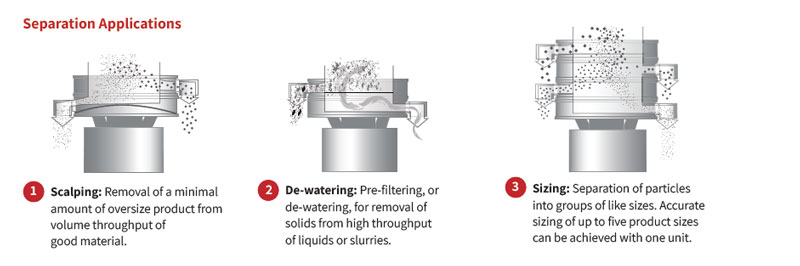

Vibratory Sieve is used for grading, filtering and removing impurities of materials in different forms such as powders, granules and liquids. It is mainly divided into circular and linear types. We can choose according to the material properties and purpose of use.

What is Vibratory Sieve used for?

Filter and remove impurities

Vibratory sieves can be used to filter various slurries, including paints, inks, colorants, paints, latex paints, aluminum slurries, soy milk, juice, beverages, slurries, pulp, waste liquids, Chinese and Western medicine solutions, and more. They can be used to separate impurities and particulate matter from liquids or slurries. For different types of liquids or slurries, we offer a choice of circular vibrating screens, 450mm filter vibratory sieves, and high-frequency vibratory sieves:

The circular vibrating screen is used to filter common liquids, powders, or small particles within 500 mesh, such as soy milk and juice.

The 450mm filter vibratory sieve is more suitable for small batches of fluid-rich liquids or slurries within 400 mesh, rapidly removing insoluble matter from various slurries.

The high-frequency vibratory sieve is used to filter materials with a feed size of less than 30mm, fine particles, high viscosity, and high concentration. Using a high-frequency vibration of 3,000 vibrations per minute, it quickly breaks down material tension during filtration, allowing the material to pass through the screen quickly and achieve effective filtration, such as slurries and ceramic glazes.

Impurity Removal

Vibratory sieves use a single-layer screen with two outlets: the upper outlet removes impurities, and the lower outlet is for finished products. They are commonly used to remove large particles and foreign matter from powders and granular materials. Circular and linear vibrating screens are available:

Circular vibrating screens are used to remove irregularities or large particles from small particles or powders, primarily powders such as flour and starch.

Linear vibrating screens are used to remove impurities from non-sticky particles or powders within 400 mesh, primarily granular materials such as peanuts, soybeans, corn, activated carbon, and fertilizers. They are ideal for large production runs, reaching up to 30 tons per hour.

Uniform classification

Vibratory Sieve has 1-6 layers of screen mesh to choose from, which can screen materials into 2-7 different specifications. The circular vibrating screen can reach up to 5 layers, but we recommend choosing 3 layers at most for the best effect; while the linear vibrating screen can reach 6 layers of screen mesh. It is commonly used for grading materials such as rice, seeds, graphite powder, gypsum powder, etc.

What are the advantages of the Vibratory Sieve?

The Vibratory Sieve configuration varies depending on the properties of the material being screened. For dusty materials, a linear vibrating screen equipped with a dust collector can be used. The dust generated during screening is directly drawn into the dust collector for purification. For materials with agglomerates or particles, an ultrasonic vibrating screen equipped with wipers can be used to forcibly break up the material without damaging it. Furthermore, to reduce manual feeding, a dust-free feeding station can be installed on a circular vibrating screen or a linear screen, reducing labor costs.

The Vibratory Sieve can be used for screening, filtering, and impurity removal of powders, granules, and liquids. It is commonly used in industries such as food, chemicals, pharmaceuticals, mining, building materials, and environmental protection. It provides efficient and flexible solutions for diverse material screening needs.

| Application Scenarios | Screening Materials | Mesh Size | Production Capacity | Model/Type | Remarks |

| Mine Aggregate Screening | Quartz Sand, Limestone | 20-80 Mesh | 20-30t/h | Linear Vibrating Screen | Adjustable amplitude, suitable for wet and sticky materials |

| Starch fine screening | Potato starch | 200 mesh | 500 kg/h | Rotary Vibrating Screen + Ultrasonic Vibrator | Ultrasonic anti-clogging, screening efficiency increased by 40% |

| Food Processing | Flour, seasonings | 80-120 mesh | 2-5 t/h | Linear Vibrating Screen | Fully enclosed design, compliant with GMP standards |

| Chemical Powder Processing | PVC Resin Powder | 100 Mesh | 3-8t/h | DH Series Rotary Vibrating Screen | 304 Stainless Steel, Multi-Layer Classification |

| Metallurgical Ore Powder Classification | Iron Powder, Titanium Dioxide | 80-200 Mesh | 15-30t/h | Linear Vibrating Screen | Dual Motor Excitation, Screening Accuracy 98.7% |

| Pharmaceutical Intermediate Screening | Traditional Chinese Medicine Powder, Western Medicine Granules | 300 Mesh | 200-500 kg/h | Ultrasonic Vibrating Screen | PLC Control, Cross-Contamination Prevention |

| Ceramic Slurry Filtration | Kaolin, Glaze | 325 Mesh | 1-3 t/h | High-Frequency Vibrating Screen | Polyurethane Screen, High Wear Resistance |

| Environmentally Friendly Solid Waste Treatment | Construction Slurry, Waste Residue | 40-100 Mesh | 5-10t/h | Vortex Vibrating Screen | Used for slurry dewatering and clean production |