stainless steel round sieve

Monday August-18 2025 16:58:31

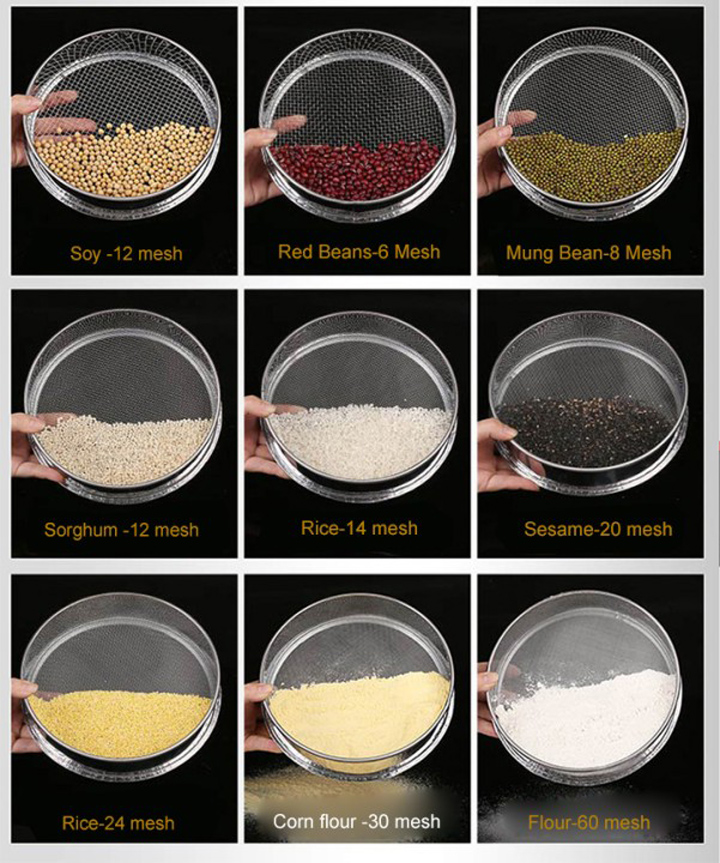

Stainless steel round sieves can be used to sieve powders and granular materials and are commonly used in laboratories. The mesh size determines the choice of sieve frame, which includes punched plate (mesh size ≥ 3 mm), electroformed (mesh size 500 mm - 5 microns) and metal woven mesh (mesh size 2.36 mm - 0.038 mm).

Stainless steel round sieve can be used for screening dry or wet materials such as soil, pharmacopoeia, chemical raw materials, sand, gravel, flour, etc. The sieve frame diameter is optional: 75mm, 100mm, 200mm, 300mm, 400mm, and can be customized according to needs.

what is the principle of stainless steel round sieve?

Stainless steel round sieves operate on two principles: mechanical screening and manual screening. Mechanical screening involves screening materials in conjunction with a test sieve machine. The screen frame can be equipped with 1-12 layers, allowing the material to be sorted into 2-13 different specifications. The excitation force generated by the vibrating motor vibrates the screen box and mesh. Material enters the screen box from above. The excitation force forces smaller particles through the mesh pores, while larger particles are retained. This allows the material to be separated according to different particle sizes. Manual screening generally uses a single-layer mesh screen, primarily used to remove impurities from the material and is suitable for processing and testing.

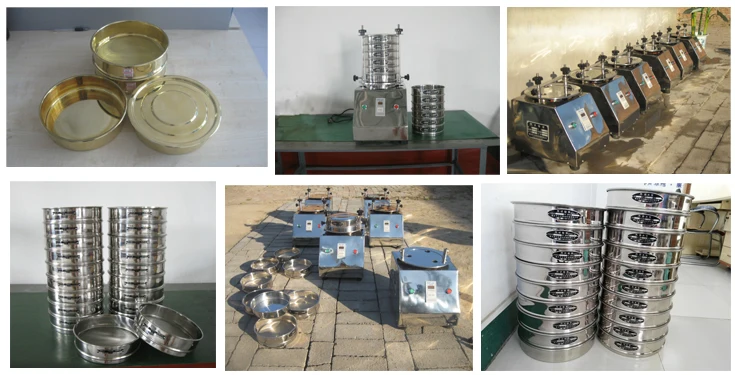

Stainless Steel Round Sieve Frame Sample

Stainless steel round sieve is a sieve mesh and sieve frame made of 304/316L stainless steel. It can be used to detect material particle size in the range of 125 mm - 20 microns. The height and diameter of the sieve frame can be customized according to needs.

| Material | Stainless steel | Color | Silver |

| Brand | Dahan Machinery | Style | Mesh filter |

| Auto shut-off | No | Product wire diameter | 0.025-2.0mm |

| Grid size | 125mm - 20 microns | Sieve height | 3.5cm, 5cm, 6cm, 7.5cm, 8cm, 10cm, etc. |

| Price | $200.00 (1-4 pieces) $1,080.00 (>=5 pieces) | ||

| Fine mesh | The stainless steel round sieve is made of ultra-fine mesh, which is very suitable for all kinds of baking powder, baking soda, powdered sugar on cakes, etc. | ||

| High quality | The sieve is made of high-quality food-grade stainless steel, which is non-corrosive and lightweight. | ||

| Advantages | The stainless steel round sieve can filter fine particles in flour. | ||

| Multi-purpose | The stainless steel round sieve can not only filter tea, coffee, flour, sugar, spices, but also fruits, beans, juice, etc. | ||

| Easy to clean | Just wash it with warm water and store it in a dry place. There is no complicated cleaning process. | ||

What is a stainless steel round sieve used for?

Stainless steel round sieve can be used for dry and wet screening of powder and granular materials in food, chemical, pharmaceutical, building materials, mining and other industries.

Food Industry: Stainless steel round sieve can be used in screening and grading operations in food processing. It can remove impurities, separate and control particle size of raw materials to ensure product quality and safety.

Pharmaceutical industry: In the pharmaceutical process, stainless steel round sieve is used for screening and particle size control of pharmaceutical powders. It removes impurities and ensures the purity and quality of medicines.

Chemical industry: Stainless steel round sieve is widely used in screening and classifying chemical raw materials. It can control the particle size of chemical products to ensure product uniformity and quality.

Building materials industry: In building materials production, stainless steel round sieve is used for screening and grading of stone, sand, cement and other materials. It can improve production efficiency and ensure product quality and consistency.

Mining industry: In mining and ore processing, stainless steel round sieve is used for screening and grading of ore. It can divide ores into different specifications according to different particle size requirements to facilitate subsequent mineral processing work.

What is the difference between a strainer and a stainless steel round sieve?

| Difference | strainer | stainless steel round sieve |

| Material | Made of lightweight rust-proof stainless steel, easy to sift, strong, durable and rust-proof | 304 stainless steel, durable stainless steel structure, light but strong |

| Diameter | 20 cm, height 5 cm, very suitable for use as a flour sieve, for sprinkling flour, baking powder, baking soda, salt, sprinkling cocoa or powdered sugar on cakes, etc. | 15 cm, height 4.5 cm, 40 mesh |

| Convenience | After use, just wash with water or wipe with a wet napkin, then stack in a drawer or hang with a ring | Easy to clean and maintain, in line with hygiene requirements |

| Application | With uniform mesh, suitable for sieving flour and frosting, very suitable for bakeries and home kitchens, also suitable for sieving powder, baking powder, almond powder and other powders | Widely used in food, medicine, chemical industry and other fields |

How is Stainless steel round sieve screened?

Stainless steel round sieve uses vibration force and gravity to screen and classify materials.

The specific process is as follows: the material enters the screen surface of the circular screen from the feed port, and the circular screen starts to vibrate, causing the material to roll and jump on the screen surface. Smaller particles fall through the sieve holes into the discharge port below, while larger particles cannot pass through the sieve holes and continue to roll on the screen surface. In this way, the materials are divided into different levels according to their particle size to achieve the purpose of screening.

Vibration force can change the clogging of screen holes during the screening process and improve screening efficiency. At the same time, the size of the sieve holes will also affect the screening results. Different sieve hole sizes can achieve different particle size classifications. The entire screening process can be controlled and adjusted by adjusting the vibration force, screen hole size and screen form.

Why should you use a stainless steel round sieve?

The entire sieve frame and mesh bucket of Stainless Steel Round Sieve are made of stainless steel, which has good acid and alkali corrosion resistance, is clean and hygienic, and easy to clean. It is the preferred equipment for testing materials in the food, medicine, and chemical industries.