1. The screen can be as fine as 20 microns, and the ultrasonic device automatically clears the screen, and the screened powder will not adhere or block the mesh.

2. The high-frequency and low-amplitude vibration can ensure that the fine powder passes through the screen quickly, and at the same time avoid the occurrence of static electricity, agglomeration and blockage.

3. You can choose to design 1-5 layers of screen mesh, and one machine can separate 2-6 specifications of materials at the same time.

4. The screening accuracy can be increased by 1-70%, the output can be increased by 0.5-10 times, and the processing capacity is 2-10 times that of the ordinary vibrating screen.

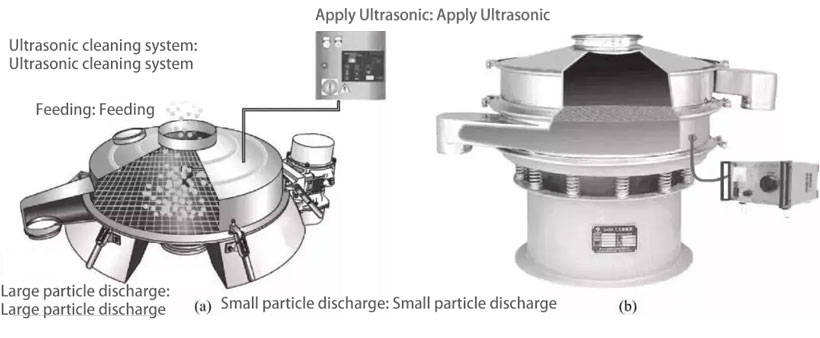

Hierarchical display of ultrasonic vibrating screen

Internal displacement transducer Ultrasonic Vibrating Screen:

Screening of non-corrosive common powder materials, difficult to clean, high damage rate and low price;

External displacement transducer Ultrasonic Vibrating Screen:

suitable for all powder material screening situations, not easy to damage, easy to clean, high price.

Carbon steel Ultrasonic Vibrating Screen:

The most conventional machine material, only used for screening of general materials.

Stainless steel Ultrasonic Vibrating Screen:

It can be designed so that only the part in contact with the material is made of stainless steel, or it is made of stainless steel. It is usually used for material screening in the food and pharmaceutical industry. It has high safety standards and will not rust.

Ultrasonic vibrating screen can convert 220V, 50Hz or 110V, 60Hz electric energy into 18KHz high-frequency electric energy, and then send it into the ultrasonic transducer to convert into 18KHz mechanical vibration. The ultrasonic system applies high-frequency vibration to the screen, which has a high vibration frequency. , low amplitude, and then evenly distributed in the entire grid through the energy conduction ring, the frequency of vibration breaks the static bond between particles, promotes the vertical movement in the screen, accelerates the screening speed of powdery materials, and Prevents oversized and undersized particles from clogging or clogging the mesh.

| Model (mm) | Test material | Ordinary screening machine | Ultrasonic vibrating screen | Mesh | |

| Screen mesh | Test Results | ||||

| Φ1000 | Silicon carbide | 500 | Can not be sieved | 500 | 1500KG/H |

| Φ1000 | Tungsten carbide powder | 600 | No fine powder is sifted out in 15 minutes | 600 | 30KG/H |

| Φ1000 | Vitamin C powder | 400 | 1KG/H | 100 | 120-150KG/H |

| Φ500 | pollen | 400 | No fine powder is sifted out in 15 minutes | 400 | Screen out 20% in 15 minutes.Fine and effective classification can be carried out in fine workmanship. |

| Nickel powder, cobalt powder | 325 | The sieve meets the requirements three times | 400 | Screen once to meet the requirements | |

| Φ450 | NdFeB powder | 300 | 32.2% sieve residue in 30 minutes | 300 | 6.9% residual sieve in 30 minutes |

1. Size classification: The separation of particles from a material into groups of comparable size.

2. Gravity Filtration: Remove solids from liquids and slurries.

3. Product recycling: remove solids from waste products or clarify waste liquid for later use.

4. Screening: separating some oversized particles from a certain amount of material.

Ultrasonic vibrating screen is used for 400 mesh, 500 mesh and 600 mesh fine materials such as graphite powder,diamond, glass powder, silicon aluminum powder, slurry, white latex, alumina, quartz sand, lithium battery cathode material, metal powder, phosphor , Titanium powder, micro mineral powder, sulfur powder, high nickel ternary cathode material, epoxy powder, traditional Chinese medicine powder, catalyst, lithium battery powder,stainless steel metal powder, chili powder, diamond, matcha powder, etc.

| Material picture | Material name | Material characteristics | Advantages of ultrasonic vibrating screen——Material consultation |

|

Silicon carbide | High hardness, small expansion coefficient, brittleness, good thermal conductivity, etc. | The small impact force and small vibration ability can prevent the silicon carbide from being damaged by the vibration ability during the screening. |

|

Wood flour | Light specific gravity, fluffy material, easy to agglomerate | The high vibration frequency can suppress clumping and fluffy problems. |

|

Lithium battery materials | It has good electrical conductivity and anti-classical properties, light weight, poor material fluidity, high viscosity, low output | solve the problem of powder proportion, low material flowability, high viscosity, low output and low screening |

|

Chinese medicine powder | light specific gravity, easy to clump, easy to adhere | Fully sealed screening method, high-frequency screening can solve screening problems such as small particle size, light weight, and easy suspension |

|

Epoxy powder | a thermosetting powder coating with corrosion resistance and toughness | solve the problem of low powder proportion, corrosion resistance and long service life |

|

Nickel Ternary Cathode Material | High capacity, low cost, poor material fluidity, high viscosity, low output | Solve the problem of poor fluidity of materials, high viscosity, low yield and low sieving |

|

Sulfur powder | Flammable, disinfection and sterilization, laxative. The fineness is 200 mesh, 325 mesh, 400 mesh and 500 mesh, etc. | Solve the problem of low powder specific gravity, product corrosion resistance and long service life |

|

Graphite powder | Adsorption, easy to clump, strong viscosity, high static electricity and other characteristics | Solve the screening problems of easy clumping, strong viscosity, high static electricity, ultra-fine powder, etc. |

|

coating | Sticky and light, agglomerate into particles, sometimes dusty, waste raw materials and pollute the environment | Fully enclosed screening structure solves the screening problem of sticky and light, agglomerated particles |

Graphite powder ultrasonic vibrating screen

Ultrasonic vibrating screen for alumina powder

Ultrasonic vibrating screen mesh replacement

The larger the model, the wider the effective diameter, and the higher the screening output. The manufacturer supports customizing different models and types.

| Model | Screen diameter | Screen specification | Power (kw) |

| DHC-400 | Φ350 | 80-600 meshes | 0.18 |

| DHC-600 | Φ550 | 0.25 | |

| DHC-800 | Φ750 | 0.55 | |

| DHC-1000 | Φ920 | 0.75 | |

| DHC-1200 | Φ1120 | 1.1 | |

| DHC-1500 | Φ1420 | 1.5 | |

| DHC-1800 | Φ1720 | 2.2 |

Ultrasonic connector: It solves the problem of blocking the screen like adhesion.Improves the screening and cleaning efficiency.Solves the screening problems such as adsorbing strongly, easy to agglomerate, high static electricity, and so on.

Screen: The screen mesh can be up to 600 mesh.

Discharge valve: Adjust the discharging speed through valve as your required, so that increasing the screening accuracy.

Buffer board & dust cover: The buffer board makes the materials flow into the screen surface evenly.Dust cover prevents the dust flying.

Quick clamping: Quickly open the clamp ring to replace the screen.Reduce labor intensity.

Max ultrasonic power: 50 Weff 100 Weff or 200 Weff

Output frequency: 33 - 37 kHz (frequency variation)

Frequency: 50/60 Hz

Mesh sizes: from 20mesh(850μm) to 635mesh(18μm)

This ultrasonic system has been designed so that it can be retrofitted onto any new or existing vibrating sieve/separator.

1. Increase the height of the screen cover: increase the material holding capacity of the upper screen frame to prevent material splashing, and an observation window can be installed on the screen cover to facilitate observation of the screening situation in the screen;

2. Gate design: an active valve is added to the discharge port, which can close or adjust the flow of the discharge end, and can artificially control the duration of material screening and improve the fineness of material screening;

3. Integrated silo type: the feed port is connected to the feeding silo, and the silo has its own adjustable valve, which can control the feeding flow while cooperating with the feeding equipment.

4. Explosion-proof motor: BZDL explosion-proof vertical vibration motor is used to meet the screening requirements or usage scenarios of some flammable and explosive materials;

5. Gas protection device: It is mostly used in the field of 3D printing industry. It has a more airtight design and can be filled with inert gas to prevent pollution while strictly screening.

Deblinding systems for ultrasonic vibrating screen can be easily retrofitted to any existing shaker, and we offer a range of screen designs to suit all sizes and applications.

Single waveguide ring: Consists of a self-supporting screen and velocity transfer plate that provides even activity across the screen while also providing a solid connection for the probe.

Variable number of waveguide rings: This design is especially suitable for larger diameter mesh frames, ensuring maximum capacity on screens up to 2m in diameter.