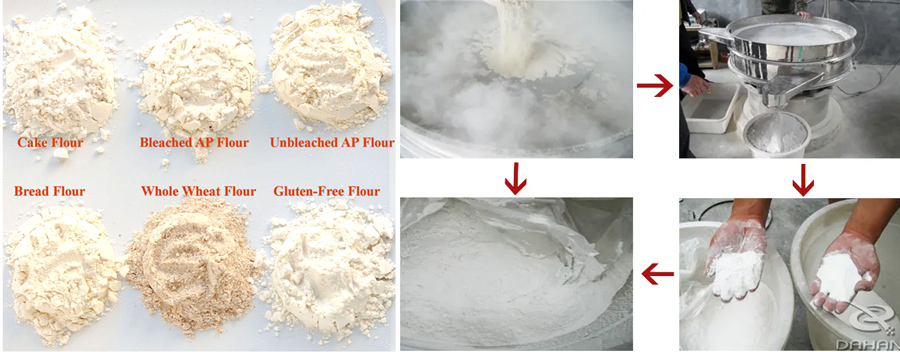

The Commercial Flour Sifter vibrates the motor to evenly spread the flour on the sieve surface in a circular shape. The flour that meets the requirements will pass through the upper sieve and be discharged from the outlet of the lower layer. The impurities or flour agglomerates that do not meet the specifications are intercepted in the upper layer. , Excluded from the upper discharge port to complete the removal of impurities in the flour and improve the quality of the flour.

Commercial flour sifter is made of SS304 or 316L stainless steel, and the machine undergoes a strict polishing process to avoid any chance of cross-contamination between batches, meeting the stringent engineering and safety standards required by the food industry.

Before the flour enters the dough mixer, safety screening should be carried out to prevent foreign matter from entering the next process, causing food safety problems and causing consumer complaints.

The Commercial Flour Sifter can be installed under the flour silo, and can also be used with vacuum feeder, screw conveyor, vibrating feeder and other feeding equipment to realize flour feeding. It can process 500-10000 kg of flour per unit hour, and the processing capacity is Dozens of times that of traditional manual screening methods.

The Commercial Flour Sifter can be used in grain processing plants such as wheat and corn, as well as in bakeries, pastry workshops, etc., to process various powders such as flour, powdered sugar, tapioca flour, and corn flour.

1. Large bakery, boutique pastry processing enterprises

2. Integrated processing enterprises such as dried noodles, steamed buns, steamed buns and dumplings

3. Ready-mixed powder

4. Other food processing enterprises

The most conventional round flour vibrating sieve occupies a small space and can be used for grading or removing impurities of flour of different fineness.

It is only used for removing impurities in flour, and is generally used as a "quality inspector" in the front of the flour production line.

The flour sieving machine with the largest processing capacity, air impact sieving, solves the problem of flour static electricity.

1. Improve product quality

Ensure the high quality of your flour by eliminating potential contaminants, ensuring the safety, hygiene and quality of the final product.

2. No material storage or blockage

The structure of the machine is exquisitely designed without dead ends, and it is easy to clean without hiding materials. The built-in silica gel mesh cleaning pinball can clean the mesh surface at any time to avoid the blockage of the mesh.

3. Automation

When using, just turn on the power and pour in the flour, and the commercial flour sifter will automatically discharge the material, which can sieve 3000 kg of flour in 5-10 minutes, or even faster! It can also be directly matched with the feeding device, saving time and labor costs

4. Clean and hygienic

The food is made of 304 stainless steel, polished inside and outside, smooth and free of material, easy to clean, and avoid cross-contamination between different batches of flour.

5. Easy to operate

The compact size of commercial flour sifter meets industrial and commercial needs with minimal headroom and floor space, and can fit comfortably into any production line.

Note: Different models of commercial flour sieves have different output, please choose according to your needs, the larger the value of the model, the larger the output will be.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

| Raw material | Specific gravity | Mesh | Model | method | processing capacity (kg/hr T/hr) |

| Glucose powder | 0.8 | 6、20 | DH-1200-2S | Dry | 2000㎏ |

| wheat starch | 1 | 250 | DH-1200-1S | Wet | 3200 T |

| Flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏ |

| Rice flour | 0.5 0.8 | 100 | DH-1000-1S | 300 ㎏ | |

| Skim milk powder | 0.57-0.7 | 24 | DH-1200-1S | 3000㎏ | |

| Whole milk powder | 0.57-0.8 | 12 | DH-1000-1S | 1600㎏ | |

| Corn flour | 0.6 | 40 | DH-1000-1S |

For different enterprise scales and processing volumes, Dahan Machinery has designed three targeted solutions.

| Plan A | Plan B | Plan C | |

| Glucose powder |  |

|

|

| Mesh | 20 mesh (aperture: 0.85mm) | 20 mesh (aperture: 0.85mm) OR 30 mesh (aperture: 0.6mm) | 20 mesh (aperture: 0.85mm) OR 30 mesh (aperture: 0.6mm) OR 40 mesh (aperture: 0.425mm) |

| Capacity | 500-2000kg/hour | 2000-3000 kg/h | 2000-10000 kg/h |

| Configuration | Strainer, vibro sifter | Direct discharge sifter, dust-free feeding station | Fully automatic multi-point feeding system |

| Illustrate | Bag flour → unpacking → manual flour feeding → filter sieve & vibro sifter → turnover bucket → noodle mixer & mixer | Flour in bags→unpacking→manual feeding→direct discharge sifter & dust-free feeding station→vacuum conveying→dough mixer & mixer | Bulk truck → 40 tons buffer storage bin → airflow screening machine & dust-free feeding station → dust removal → weighing system → dough mixer & mixer |

Processing material: cassava flour

Output: 33-4t/h

Screening mesh: 60-100 mesh

Before using manual sieves to sieve flour, the efficiency was low and the production capacity did not match. Later, we also purchased screening equipment through middlemen. Because they did not understand the screening process, the selected models did not match, resulting in substandard screening accuracy and output. , can not meet the production demand. Now we use the commercial flour sifter customized by our company, which can not only connect with the upper and lower processes, but also reduce the manual operation links (more…)

Processing material: milk powder

Output: 1 ton~8 ton/hour

Screening mesh: 8-40 mesh

With the development and progress of society and the improvement of people's living standards, the public's requirements for food safety and hygiene are getting higher and higher. Major food companies control food safety from the source of food production, and conduct a safety protection sieve before milk powder enters the packaging machine. In order to prevent foreign matter from entering the next process, causing food safety problems and causing consumer complaints. (More…)

Regular commercial flour sifter VS ultrasonic commercial flour sifter

Steps to replace the screen