1. Fine sieving—with airflow feeding function, feeder crushing agglomerate function and airflow coarse sieving function, accurate sieving and grading standard, no super-diameter mixing phenomenon, sieve residue is 0 (common vibrating screen is difficult to achieve ).

2. Finer screening and higher efficiency - the screening efficiency can reach 85-95%, and the screening mesh can be as fine as 600 mesh (it is difficult for conventional vibrating screens to sieve fine powder above 300 mesh)

3. Large output - it can run continuously for a long time, and the output can be increased by 5-10 times or even higher than that of ordinary vibrating screen;

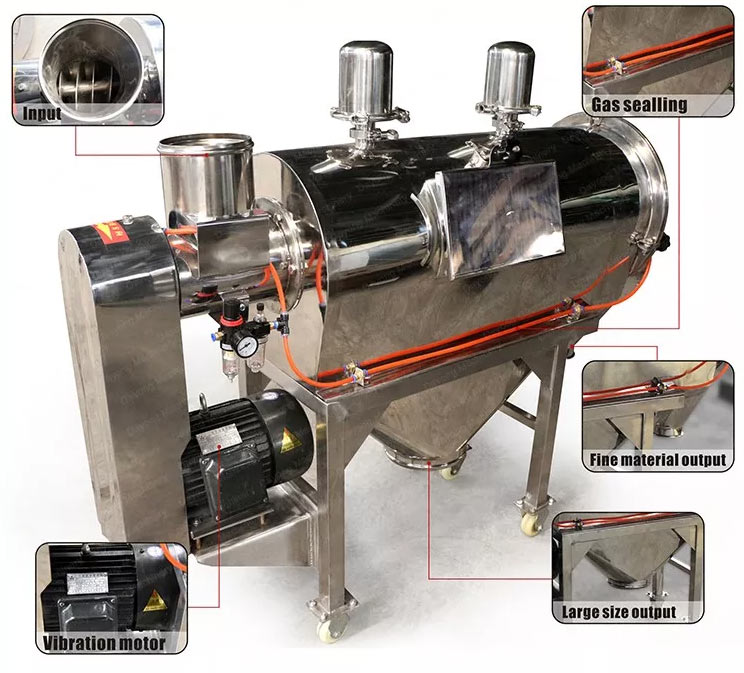

4. No dust - the structure is closed, no dust spills, and no environmental pollution.

5. Long service life - saves the investment and operation and maintenance costs of the feeding machine, and the service life of the fine screen is extended by more than 10 times.

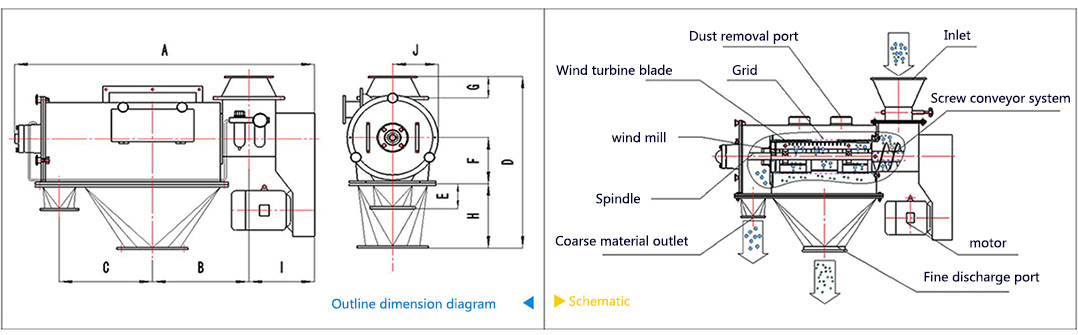

Because the Airflow screening machine has a horizontal shape and the net is cylindrical, it is placed in the machine body. The materials are mixed and atomized into the net cylinder through the screw conveying system and the air flow; the materials are simultaneously subjected to centrifugal force and pressure through the wind wheel blades in the net cylinder. The driving force of the cyclone causes the material to be sprayed through the net and discharged from the fine material discharge port, and the material that cannot pass through the net is discharged from the coarse material discharge port along the wall of the net cylinder.

| project | Airflow screening machine | vibro sifter |

| Appearance Gallery |  |

|

| Screening form | Wind Centrifugal Screening | Three-dimensional vibration screening |

| Screening capacity | 1-10 tons/hour | 100-3300kg/h |

| Screening mesh | 80-600 mesh | 2-500 mesh (difficult to screen above 300 mesh) |

| Applicable materials | fine powder | powder, granule, liquid |

| sieve | Not easy to damage | The fine mesh is easy to damage |

| model | A | B | C | D | E | F | G | H | I | J |

| WQS18-65 | 1430 | 460 | 420 | 1005 | 135 | 230 | 250 | 330 | 340 | 210 |

| WQS30-100 | 1845 | 655 | 766 | 1240 | 320 | 285 | 300 | 350 | 380 | 290 |

| WQS50-130 | 2230 | 870 | 790 | 1775 | 280 | 515 | 150 | 660 | 400 | 485 |

| model | Material | power | Be applicable |

| WQS18-65 | Q235A | 2.2KW | Screening below 500 mesh |

| SUW304 | |||

| WQS30-100 | Q235A | 4KW | |

| SUW304 | |||

| WQS50-130 | Q235A | 5.5KW | |

| SUW304 |

Airflow screening machine? How does it apply? What is the use of?

Airflow screening machine uses airflow as the power to process powder materials. It can mix and atomize the powder materials entering it with the airflow through the airflow generated inside the screen box, and then impact the screen together to realize the removal of impurities or simple screening of materials. , The characteristic of impacting through the net can also enable the machine to complete the breaking of loose agglomerated powder, and at the same time avoid the generation of electrostatic agglomeration.

Airflow screening machine is suitable for the following: rubber powder, iron oxide powder, rubber additives, sulfur powder, defatted walnut powder, plastic powder, lithium carbonate, lithium hydroxide, baking soda, alkali, coffee powder, talcum powder, Chinese medicine powder, heavy Soda ash, dry starch, oat bran, antioxidants, fly ash, wood flour and other materials

| Material name | Way of working | Screen (mesh) |

WQS18-65 (kg/h) |

WQS50-130 (kg/h) |

| Light calcium | Dry | 120-180 | 600-1000 | 1000-2000 |

| Heavy calcium | 400 | |||

| Active calcium | 500 | |||

| Slag powder | 300 | |||

| Starch | 300 | |||

| Zinc powder | 320 | |||

| Fly ash | 120-200 | |||

| Iron oxide black | 500 | |||

| Iron oxide red | 500 | |||

| Chinese medicine powder | 120-160 | |||

| Quartz powder | 180-270 | 2000-3000 | ||

| Flour | 100-180 | 200-300 | 500-1000 | |

| Wood flour | 100-300 | |||

| Mica powder | 300-400 |

The main part of the Airflow screening machine is composed of "drive motor, screw conveying system, wind rotor blades, grid frame".

The driving motor is used as the power source to drive the blades of the wind turbine to generate wind energy, which will be sent into the screen box by the screw conveying system. The wind energy generated by the blades makes the light and fine powder materials in a state of flying and impacts through the net to complete the screening of materials.

Because the grid frame does not bear the material pressure, and the wind force passing through the screen does not cause wear and tear, the screen is not easily damaged and has a longer service life.

Sift the flour

Sieving clean coal

Screen replacement video

Food industry: flour sieving, ingredient inspection screening, milk powder screening, baking mix de-agglomeration or pre-packaging inspection

Chemical industry: general fine powder classification, nylon fleece depolymerization, powder depolymerization, powder coating inspection and screening

Pharmaceutical industry: check the screening of raw materials, classification of active ingredients of drugs