1.Prevent screen clogging - Screens are often blocked by strong adsorption, static electricity and light specific gravity from caking of particles. The ultrasonic vibrating screen successfully breaks this static bond between powder particles; thus preventing the screen from clogging.

2.Suitable for fine powder separation - fine powder agglomerates due to electrostatic bonding, which is not easy to separate by ordinary sieving machines, and sieves powder on a screen as fine as 20 microns.

3.Improve productivity and efficiency - With the ultrasonic sieving machine, there is little or no blockage in the screen, and the particles can easily pass through the screen, thus increasing the screening capacity tenfold

4.No dust - the ultrasonic vibrating screen operates at high frequency and low amplitude. Due to the low amplitude, there is no dust during the screening process.

5. longer service life -- ultrasonic system automatic cleaning, no need to increase the external device, protect the fragile screen, reduce the occurrence of damage.

Ultrasonic sieving machine to convert 220V, 50Hz or 110V, 60Hz electrical energy into high frequency electrical energy such as 18KHz, input ultrasonic transducer, and turn it into mechanical vibration such as 18KHz, frequency conversion device is to change the vibration frequency of ordinary sieving machine, generally sieving machine The vibration frequency of the machine is 1460 times per second, while the vibration frequency of the ultrasonic sieving machine can reach 36,000 times per second, which increases the vibration frequency of the material in the same unit time, thereby increasing the number of times the material passes through the screen holes in the same time, eliminating the need for Static electricity on the sieve holes, powder agglomeration and clogging problems caused by particles inserted into the rough mesh surface, the sieving accuracy is higher and the output is higher.

Ultrasonic Sieving Machine's biggest feature is that it can easily handle light fiber, eving powder that is easy to adhere to or that is difficult to screen. Ultrasonic Sieving Machine can be roughly divided into two functions: stain removal and grading. Generally, Ultrasonic Sieving Machine does not make liquid filtering:

1. Removing impurities: It is used to remove parts that do not meet specifications or cannot be used in a material, so that the material can be further processed;

2. Particle size classification: depending on different sizes of the same material or different materials of different sizes. Ultrasonic Sieving Machine can be divided into 2-6 kinds of eving materials according to specified size, which can be used to separate products of different purposes or different prices.

You can choose an ultrasonic sieving machine with different materials, layers and designs according to the screening material, purpose of use and other conditions.

1.Different materials

All carbon steel: the most common machine material, usually with surface painting treatment, low cost, suitable for processing ordinary materials.

Contact part with 304 stainless steel: The part in contact with the material is made of stainless steel, and the bottom barrel of the machine is made of carbon steel. Under relatively loose requirements, it can meet the hygienic standards or special requirements of material handling at a low cost.

All 304 stainless steel: The whole machine is made of stainless steel, which is usually used in food, medicine and some chemical industries, and meets the hygiene standards of food industry equipment.

2.Different layers

The most suitable number of sieve layers for an ultrasonic system is 3 layers, and an additional ultrasonic device is required for more than 3 layers.

The role of the single-layer Ultrasonic Sieving Machine is to remove impurities from bulk materials or to perform precise separation of two materials of different sizes.

The role of Ultrasonic Sieving Machines with two or more layers is more inclined to accurately separate materials of different sizes. If the number of layers of the Ultrasonic Sieving Machine is set to N, then the final material types that can be separated are N+1.

3.Different designs

1. With gate: The discharge port is equipped with a switchable valve, which can extend the material screening time and improve the screening accuracy by closing the valve;

2. With silo: with the feeding hopper, can control the feeding flow, automatic feeding;

3. Removable: Removable wheel can rotate 360° and can be fixed, which is suitable for frequently changing screening field.

4. In-line type: large output of fine powder impurity removal equipment, generally used In the front end of the production line.

If you have other questions or design needs, please contact us, we provide you with free help!

Technical parameters are provided below! Customization services are also ready for you to contact.

| Model | Screen diameter | Screen specification | Power (kw) |

| DHC-400 | Φ350 | 80-600 meshes | 0.18 |

| DHC-600 | Φ550 | 0.25 | |

| DHC-800 | Φ750 | 0.55 | |

| DHC-1000 | Φ920 | 0.75 | |

| DHC-1200 | Φ1120 | 1.1 | |

| DHC-1500 | Φ1420 | 1.5 | |

| DHC-1800 | Φ1720 | 2.2 |

1. The vibration frequency of the ultrasonic sieving machine is 36,000 times per second, which can quickly decompose the attachments, and the pass rate of the sieve surface can be increased by 50%-400%. The ordinary sieving machine may easily stick to the mesh holes in the process of sieving fine powder. , leading to build-up, which reduces yield and product quality, while an ultrasonic sieving machine can make it easier for particles to pass through the mesh, preventing blinding, or blockage.

2. Due to the elimination of screen clogging, the product quality is consistent throughout the production process, and there is no need to stop the machine to clean the screen, reducing the risk of downtime and reducing production costs.

3. Because Ultrasonic sieving will not block the screen, the screen can be cleaned without stopping, and the output is 0.5-10 times that of the ordinary sieving machine.

| Model | Test material | Ordinary Sieving Machine | Ultrasonic Sieving Machine | ||

| Mesh | Test Results | Mesh | Test Results | ||

| φ1000 | Silicon carbide | 500 | cannot be sieved | 500 | 1000KG/H |

| Tungsten carbide powder | 600 | 15 minutes without sifting out fine powder | 600 | 30KG/H | |

| Vitamin C Powder | 100 | 1KG/H | 100 | 120-150KG/H | |

| φ600 | pollen | 400 | 15 minutes without sifting out fine powder | 400 | About 20% fine powder is sieved in 15 minutes, and finer grading is possible |

| φ1000 | Nickel, Zinc, Cobalt Powder | 325 | 10KG/H | 400 | 300KG/H |

| Emery powder | 400 | Cannot be sieved | 300 | 13000KG/H | |

1.Ultrasonic generator – The ultrasonic generator for the vibrating sieve can either be UF08 or GTS30. Its specifications are as follows:

Power: 220V, 50/60Hz, Single-Phase

Power Consumption: 1A (Max.)

Output Frequency: 36KHz

Operating Mode: Continuous Mode / Pulse Mode

Box Dimension (WxHxD): 165 x 230 x 400mm

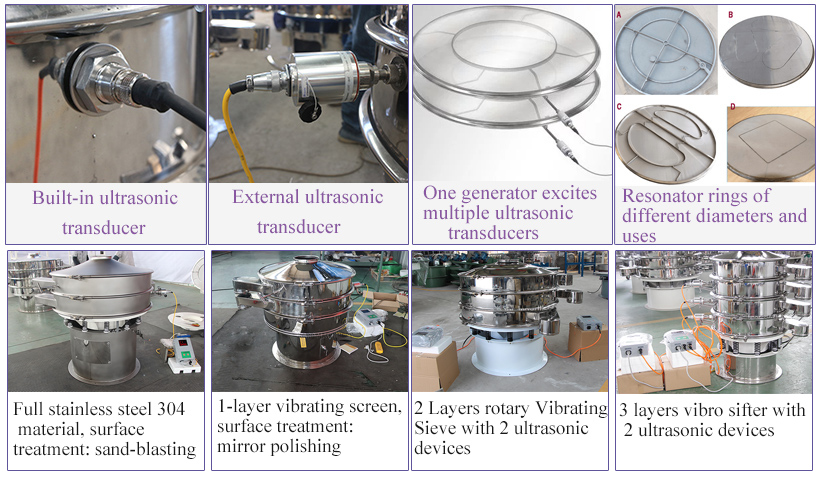

2.Transducer – The transducer has a stainless steel SS304 casing and has above screen position.

3.Resonance ring or conduction ring

1. Our design of the grid is also divided into external type and built-in type. The main difference is that the positions of the transducers on the grid are one external and one built-in. The external displacement transducer is installed outside the screening machine and will not come into contact with the material, which avoids the damage to the transducer when screening some corrosive materials.

2. For large screen frames, a single large or multiple waveguide rings can be processed using multiple ultrasonic transducers excited by one generator.

3.Machine with one, two, three or four decks.

1. Food industry: powdered sugar, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce, fruit juice, etc.

2. Pharmaceutical industry: industrial drugs, traditional Chinese medicine powders, granules, etc.

3. 3D printing materials: titanium alloy powder, aluminum alloy powder, stainless steel powder, iron-based alloy, nickel-based alloy, titanium powder, copper powder, aluminum powder, molybdenum powder.

4. Chemical industry: resins, paints, industrial drugs, cosmetics, paints, herbal powders, etc.

5. Metal and metallurgical mines: aluminum powder, lead powder, copper powder, ore, alloy powder, electrode powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials, kaolin, lime, alumina, heavy metals Calcium carbonate, quartz sand, etc.

6. Other industries: waste oil, waste water, dyeing and finishing waste water, papermaking, additives, activated carbon, etc.

Ultrasonic sieving machine is now widely used in 400 mesh, 500 mesh, 600 mesh traditional Chinese medicine powder, alloy powder, molybdenum powder, silicon carbide, abrasive, rare earth, stainless steel powder, tungsten powder, nickel powder, cobalt powder, powder coating , quartz powder, diacetyl Powder, electromagnetic powder, silicon powder, malt powder, ribavirin, coffee powder, negative electrode material, laser powder, alumina, etc.

1. If you have ever used the screen machine, kindly pls tell us its diameter, mesh size, layers, material.

2. If never use the machine until now, pls offer us the info about material as below:

2.1. Handling material? Bulk density?

2.2. Will you do a separation or dust-removal?

2.3. Production Capacity per hour(KG/H)?

2.4. How many Layers do you need? Mesh size of each layer?

2.5. Material of Construction material?(Stainless steel or Mild Steel)

2.6. Voltage(V), Frequency(Hz), Phase(P)?