100 micron test sieve mesh for particle size analysis

Saturday May-24 2025 18:08:03

What is a 100 micron test sieve mesh for particle size analysis?

Applicable materials for 100 micron test sieve mesh for particle size analysis

The 100 micron test sieve mesh for particle size analysis is suitable for dry powder or granular materials that need to accurately control the medium particle size range (80-120μm). For materials that are easy to agglomerate (such as clay) or wet samples, it is recommended to combine dry pretreatment or wet screening technology to ensure the accuracy of the results.

Fine powder: suitable for various ultrafine or micron powders, such as pigments, talcum powder, battery powder, abrasives, fine soil particles

Ceramic and glass raw materials: ceramic powder, glass sand and other raw materials

Food industry: flour, starch, cocoa powder, spices

What types of 100 micron test sieves are there

|

Classification dimension |

woven wire mesh sieve |

electroforming sieve |

perforated plate sieve |

|

Picture |

|

|

|

|

Sieving efficiency |

high (large hole density, high powder pass rate) |

low (low hole density, fine powder needs auxiliary vibration) |

medium (regular holes but low opening rate) |

|

Aperture accuracy |

±5~10μm |

±1μm Internal |

±2~5μm |

|

Applicable material types |

Medium-fine powder (good fluidity, such as flour, cement) |

Ultrafine powder (100μm and below, such as lithium battery materials, catalysts) |

Medium-coarse powder (high hardness, such as ore, metal particles) |

|

Typical material examples |

Flour, powdered sugar, paint filler |

Lithium iron phosphate, nano titanium dioxide |

Quartz sand, copper ore powder, ceramic raw materials |

|

Application scenarios |

Conventional screening in food, chemical, building materials industries |

Precision electronics, medicine, aerospace |

Mining, metallurgy Gold, wear-resistant material classification |

|

Maximum processing capacity |

high (suitable for batch screening) |

medium (precision analysis) |

extremely high (impact resistance) |

|

Applicable material form |

dry powder, granules (easy-to-clear net) |

dry powder, fine particles (anti-static) |

coarse particles, block materials |

Features of 100 micron test sieve mesh for particle size analysis

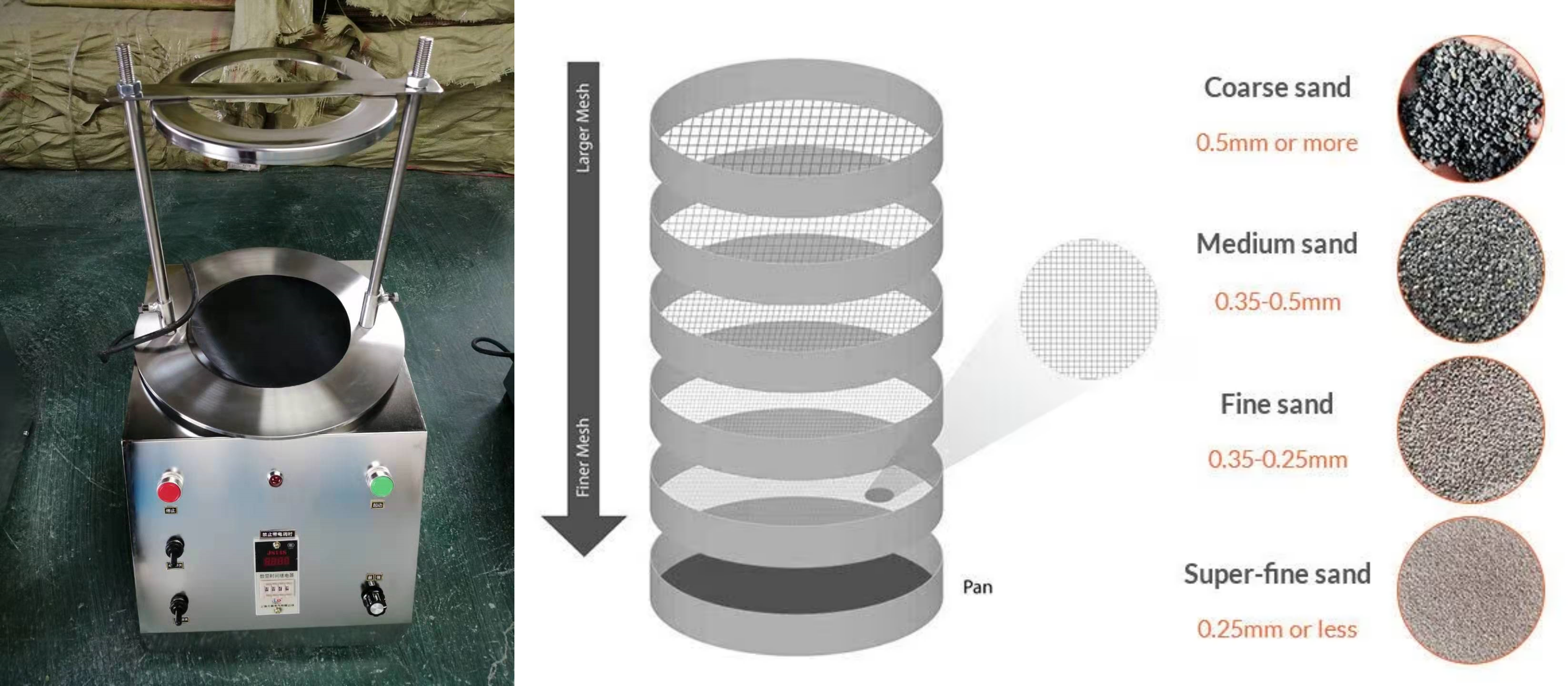

High precision: It can accurately separate particles larger than 100 microns and particles smaller than 100 microns in the material, providing accurate data for particle size analysis.

Good repeatability: Under the same operating conditions, multiple screening experiments using a 100 micron test sieve can obtain relatively consistent results, ensuring the reliability and comparability of the experimental data.

Easy operation: Whether it is manual screening or used in conjunction with vibration screening equipment, the operation process is relatively simple and easy to master, and does not require complex operating skills and professional knowledge.

Wide application: It can be used for particle size analysis in multiple industries such as pharmaceuticals, food, chemicals, building materials, and mining, and can effectively screen different types of materials.

Scope of application of 100 micron test sieve mesh for particle size analysis

The 100 micron test sieve has a wide range of applicability in particle size analysis, especially focusing on accurately distinguishing fine particles. Its 100 micron (0.1 mm) sieve hole characteristics make it a key tool for particle size control of fine powders, pigments, pharmaceuticals, food additives and some chemical products.

In geology, it is used for the particle size classification of soil and sediments to clarify the boundary between sandy and powdery components; in the pharmaceutical industry, it is used as a standard sieve for particle size control of raw materials and excipients to ensure the solubility and bioavailability of preparations; in the field of materials science, it is suitable for particle size classification of ceramic powders, metal fillers and polymer particles to optimize material fluidity and bulk density; in the food and chemical industries, it is used for particle size quality inspection of additives, pigments and catalysts to avoid process problems caused by overly coarse particles. As the core specification of the particle size distribution test sieve set, it can be combined with other mesh sieves to achieve multi-stage separation and provide quantitative data support for quality control.

The 100 micron test sieve mesh for particle size analysis is a tool with a precise 100 micron (0.1 mm) mesh, designed to grade powders, granules or suspensions by sieving. Its core value lies in its ability to accurately distinguish particles larger or smaller than 100 microns. This specific size of mesh makes it the key to quality control in many industries (such as pharmaceuticals, food, chemicals, metal powders, etc.), ensuring that the product fineness meets the standard, which directly affects the material's fluidity, solubility, bulk density and even the texture and performance of the final product.