Soil sieve accuracy standards

Thursday June-19 2025 17:38:26

The accuracy standards of soil sieves are mainly reflected in the accuracy of sieve hole size and screening results. These standards are usually formulated by national or international organizations to ensure the comparability and reliability of soil particle analysis results. The accuracy of soil sieves directly affects the accuracy of particle classification, component analysis and other results in soil tests.

Sieve hole size and specification standards

International standard (ISO14688-1:2002)

Common apertures: 2mm, 1mm, 0.5mm, 0.25mm, 0.125mm, 0.063mm, etc.

Sieve diameter: 200mm or 300mm, height 50-75mm.

Material: stainless steel wire woven mesh, the mesh diameter becomes finer as the aperture decreases (such as 2mm aperture mesh diameter is about 0.63mm).

American standard (ASTMD422-63)

Common apertures: 4.75mm (No.4 sieve), 2.00mm (No.10 sieve), 0.425mm (No.40 sieve), 0.075mm (No.200 sieve), etc.

Sieve diameter: 8 inches (about 203.2mm), height about 50mm.

Mesh wire diameter: For example, the mesh wire diameter of No.200 sieve (0.075mm aperture) is about 0.038mm.

Chinese standard (GB/T14799-2008)

Common apertures: 60mm, 40mm, 20mm, 10mm, 5mm, 2mm, 1mm, 0.5mm, 0.25mm, 0.075mm, etc.

Sieve diameter: 200mm and 300mm, height 50-70mm.

Material: high-quality stainless steel wire mesh (such as 0.075mm mesh diameter is about 0.035mm).

|

Standard system |

Representative standard |

Core requirements |

|

China's national standard |

GB/T50123-2019 |

has detailed provisions on sieve hole sequence, sieve vibration time, sample quality, weighing accuracy, result calculation, etc. |

|

American ASTM standard |

ASTMD6913/D6913M |

strictly stipulates the screening process, equipment calibration, and repeatability requirements, and pays special attention to the 0.075mm screening accuracy. |

|

International standard |

ISO17892-4:2016 |

is similar to ASTM, emphasizing operational consistency and error control, and is suitable for global geotechnical testing. |

Screen accuracy index (taking GB/T 6003.1 as an example)

|

Item |

Requirement |

|

Allowable deviation of screen size |

±1.5% of standard aperture (medium accuracy) |

|

Screen tension |

No relaxation, no obvious deformation |

|

Screen frame concentricity error |

≤0.1 mm |

|

Screen material |

Stainless steel wire (304 or 316 recommended), good corrosion resistance |

|

Screen hole shape |

Mainly square holes (for soil analysis) |

Soil sieve aperture standard

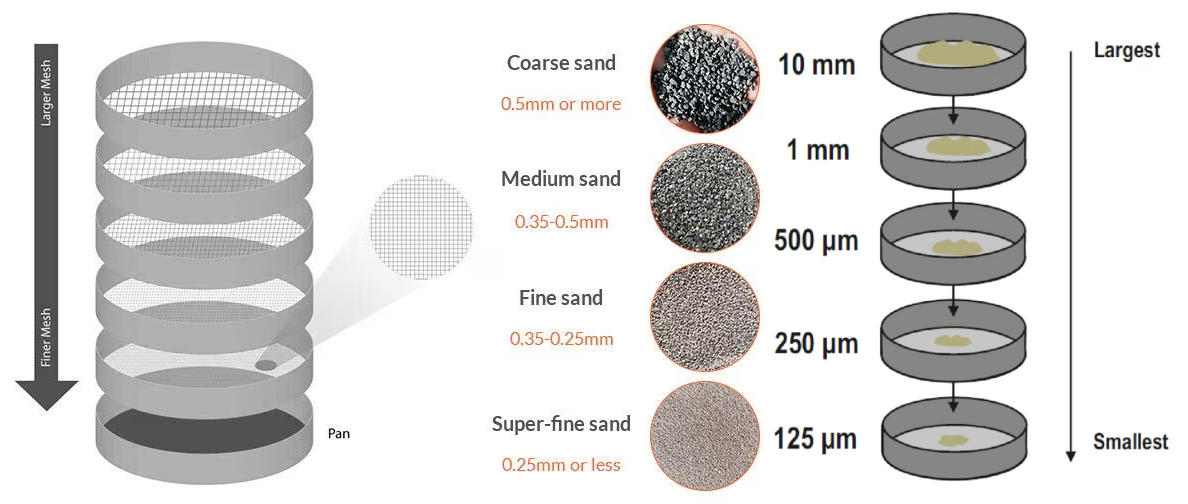

Soil particle size analysis usually uses standard sieves, and the sieve aperture is designed according to the particle size distribution requirements. ISO standards (ISO11277) are commonly used internationally, and domestic reference is often made to "Soil Particle Size Analysis Method" (GB/T50123-2019) or agricultural standards (NY/T1121.3-2006). Commonly used sieve apertures include:

Coarse particles: >2mm (such as gravel)

Sand particles: 0.05mm-2mm (subdivided into coarse sand, medium sand, and fine sand)

Powder particles: 0.002mm-0.05mm

Clay particles: <0.002mm (other methods such as sedimentation analysis are required)

Common standard sieve apertures (unit: mm): 10, 5, 2, 1, 0.5, 0.25, 0.1, 0.075, 0.05, etc.

Accuracy requirements: The sieve aperture tolerance is usually within ±5% to ensure accurate particle classification.

Common soil sieve aperture (mm) and corresponding mesh number reference

|

Aperture (mm) |

Mesh number (approximately) |

Purpose description |

|

2.0 |

10 mesh |

Coarse particle separation |

|

1.0 |

18 mesh |

Medium particle separation |

|

0.5 |

35 mesh |

Fine particle screening |

|

0.25 |

60 mesh |

Powdery soil |

|

0.075 |

200 mesh |

Clay soil/fine powder classification critical value |

In addition, there are some general requirements for the quality and performance of the soil sieve itself:

Appearance: The connection between the sieve frame and the metal mesh should be smooth and firm, the sieve should not have burrs, broken wires or other defects, and there should be no distortion, looseness or wrinkles.

Inner diameter of sieve frame: usually 200mm±5mm or 300mm±5mm.

Mesh size: must comply with relevant standards, such as wire woven test sieve, the mesh size of square holes can be up to 0.02 mm (20 microns), the mesh size of triangular holes can be up to 0.005 mm (5 microns), the sieve is woven according to B6003.1-1997 standard, and complies with international standards ISO3310-1:1990R20/3, R20, R40/3 series.