What is a wood powder inclined spiral feeder?

Friday May-23 2025 16:16:21

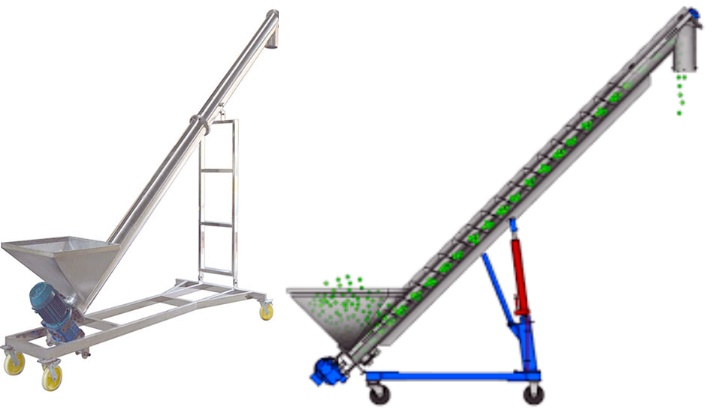

The wood powder inclined spiral feeder is a mechanical equipment specially used for conveying light and dusty powder materials such as wood powder. Wood powder has the characteristics of low density, fine particles and easy floating. It is easy to generate dust and poor material flow during the conveying process. Therefore, the sealing and stability of the conveying equipment are required to be high.

How does the wood powder inclined spiral feeder work

The working principle of the wood powder inclined spiral feeder is based on the basic principle of screw conveying. The motor drives the spiral shaft to rotate, so that the spiral blades installed on the shaft rotate in the closed conveying pipe, thereby pushing the wood powder to achieve continuous feeding along the inclined direction.

After the device is started, the motor drives the spiral shaft to start rotating through the reducer; the wood powder at the feed end enters the conveying pipeline under the action of its own weight or the auxiliary feeding device; the rotation of the spiral blade forms an axial thrust inside the pipeline, pushing the wood powder upward in the spiral direction; the tilt angle (generally 20°~45°) allows the wood powder to maintain smooth flow under the action of axial direction and gravity to avoid falling back or blocking; the material is discharged at the discharge end and enters the next process, such as storage bin, mixer or pelletizing equipment.

Due to the characteristics of wood powder being light, easy to raise dust, and fine particles, the inclined spiral feeder is usually designed with a closed structure to reduce dust leakage, and a reasonable gap is retained between the spiral blade and the pipe wall to ensure smooth material transportation and prevent blockage and overload. The whole machine has a high degree of automation during operation and is suitable for use with continuous production lines.

Differences between inclined screw feeder and vertical screw feeder for wood powder

There are obvious differences between inclined screw feeder and vertical screw feeder for wood powder in terms of structural layout, conveying method and applicable occasions. The following are the main differences between the two:

|

Differences |

Inclined screw feeder |

Vertical screw feeder |

|

Image |

|

|

|

Conveying direction |

Conveying at a certain angle (usually 20°~45°) upward |

Vertical upward conveying |

|

Applicable materials |

Applicable to light powdery materials such as wood powder and sawdust |

Applicable to granular or powdery and granular materials with good fluidity |

|

Structural form |

The spiral shaft is arranged in an inclined pipeline for easy inspection and maintenance |

The spiral body is arranged vertically and has a compact structure |

|

Conveying height |

Generally applicable to Medium and short distance transportation (1-8 meters) |

Suitable for short distance vertical transportation (<5 meters) |

|

Transportation efficiency |

Higher transportation efficiency, continuous and stable |

Small transportation volume, high requirements for uniform material feeding |

|

Energy consumption |

Relatively low energy consumption, small driving power |

High power demand, because it needs to overcome gravity to move upward |

|

Sealing |

Good sealing, reducing wood powder dust |

Generally also a closed structure, but more attention should be paid to anti-blocking design |

|

Applicable occasions |

Commonly used for connecting and conveying between equipment (such as silo to mixer) |

Mostly used in occasions with limited space and vertical transportation |

Recommended mesh number of wood powder inclined spiral feeder

40-80 mesh (about 0.18mm-0.425mm): suitable for biomass pellets, wood chip fuel, feed additives, etc. Wood powder has moderate particle size and good fluidity, suitable for most inclined screw feeders. The screw diameter is generally selected to be 150-250mm, and the speed is controlled at 50-100 rpm to ensure smooth transportation and not easy backflow.

80-120 mesh (about 0.125mm-0.18mm): suitable for wood-plastic composite materials, blockboard or high-precision chemical raw materials. Fine wood powder is more prone to dust, and a sealed tube feeder is required. The screw diameter is recommended to be 100-200mm and the speed is 30-60 rpm to reduce the risk of dust flying and clogging.

20-40 mesh (about 0.425mm-0.833mm): suitable for coarse wood powder processing, such as primary wood chip processing or compost raw materials. Coarse wood powder is easier to transport, but it causes greater wear on the spiral blades. It is recommended to use wear-resistant materials (such as stainless steel) blades, with a spiral diameter of 200-300mm and a speed of 60-120rpm.

What can the wood powder inclined spiral feeder be used for?

The inclined spiral feeder adopts a closed spiral conveying structure, and the wood powder is continuously conveyed upward along a certain inclination angle through the rotation of the spiral blade. At the same time, the conveying process of this equipment is stable and continuous, and it is suitable for wood powder feeding processes in wood processing, biomass pellets, furniture manufacturing and other industries. It is often used in conjunction with silos, mixers or briquetting equipment.

Wood powder inclined spiral feeder supplier

As a professional supplier of wood powder inclined spiral feeders, Dahan Machinery focuses on providing efficient and reliable material conveying solutions for wood processing, biomass energy and other fields. Its products use anti-blocking and anti-sticking technology, wear-resistant and corrosion-resistant materials, adjustable inclination design, sealed dust-proof system, etc. to target the characteristics of wood powder such as light weight, easy dusting, and fluctuating moisture content.

A variety of models and specifications: to meet the production needs of different customers.

Customized service: Non-standard design and manufacturing according to the customer's special working conditions and requirements.

Complete after-sales service: Including equipment installation guidance, commissioning, personnel training and subsequent repair and maintenance services.