45μm Ultrasonic Test Sieve for Fine Powder Certification

Tuesday May-27 2025 14:31:02

What is the 45μm Ultrasonic Test Sieve for Fine Powder Certification?

It is suitable for 45μm sieves, which is equivalent to particle size classification with a precision of 325 meshes, and is one of the standard requirements for the testing of many high-end powder products.

Scope of application

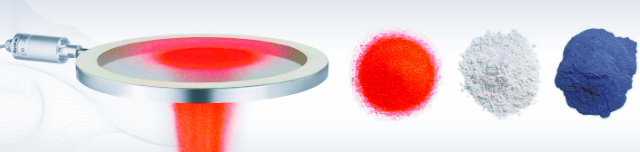

Applicable to screening or testing fine powder materials with a particle size of 45μm and below, such as: metal powder (such as tungsten powder, titanium powder, stainless steel powder), medicinal powder (such as microcrystalline cellulose, talc), food additives (such as protein powder, lactose), non-metallic mineral powder (such as silica ash, graphite, alumina powder), nanomaterial precursors, ceramic powder, etc.

Sieving principle of 45μm ultrasonic test sieve for fine powder certification

The ultrasonic test sieve consists of an ultrasonic vibration power supply, a DH-300 test sieve (host), a T200 test sieve frame, a high-frequency connecting line, and a connector. The ultrasonic generator converts electrical energy into high-frequency mechanical vibration (usually 20~40kHz) and transmits it to the sieve, so that the surface of the sieve generates micron-level high-frequency vibration waves. During the screening process, the sieve body undergoes standard mechanical vibration (such as reciprocating slapping or horizontal vibration), and the ultrasonic system transmits high-frequency vibration (such as 38kHz) to the screen, which will form a micro-vibration wave layer on the screen surface:

Increase the probability of material passing through the screen, especially critical particle size particles

Prevent fine powder from clogging and agglomeration, and increase the service life of the screen

Enhance screening resolution and repeatability

Technical parameters of 45μm ultrasonic test sieve for fine powder certification

|

Project |

Parameter |

Project |

Parameter |

|

Screen aperture |

45μm (325 mesh) |

Screen frame size |

Φ 200mm (Φ300mm is also available) |

|

Ultrasonic frequency |

20~40kHz (commonly 33kHz or 38kHz) |

Amplitude |

2~5μm (high-frequency micro-vibration) |

|

Sieving time |

0~99 minutes can be set |

Applicable material amount |

0~200g/time (depending on the material density) |

|

Power supply |

220V/50Hz |

Power |

100W~300W (including ultrasonic part) |

What can the 45μm ultrasonic test sieve for fine powder certification be used for

The 45μm ultrasonic test sieve is widely used in the field of fine powder certification. In the pharmaceutical field, it can screen the particle size of raw materials, intermediates, etc. For example, antibiotic powder and Chinese medicine extract fine powder can be accurately separated by this test sieve to ensure the solubility and bioavailability of drugs in the human body and ensure the quality of drugs. In the chemical industry, it can effectively remove impurities and classify raw materials such as paint pigments and plastic powders. For example, for latex paint pigments, the test sieve can ensure uniform pigment particle size, so that the paint has better hiding power and stability; for plastic powder screening, the performance of the produced plastic products can be more uniform.

In addition, in the food industry, the 45μm ultrasonic test sieve can be used for the certification of fine powders such as flour, condiments, and food additives. For example, coffee powder can be screened to ensure the appropriate particle size, so that the brewed coffee tastes mellower; in the metal processing industry, metal powders such as iron powder and copper powder can be accurately graded to meet the strict requirements of powder metallurgy and other processes on the particle size of metal powders, and help produce high-performance metal products.

In short, the 45μm ultrasonic test sieve is an indispensable tool for precise particle size analysis and quality control of fine powders in modern laboratories and industrial production. It combines traditional vibrating screens and ultrasonic technology to overcome the challenges encountered by traditional screening when dealing with extremely fine, easily agglomerated or electrostatically adsorbable powders. Its core value lies in the effective separation of critical particles near 45μm, reducing sample waste, and is suitable for precious materials.