How to choose test sieve size

Tuesday June-10 2025 17:39:55

Choosing the right test sieve size is crucial for particle size analysis, which directly affects the accuracy and effectiveness of the test results. Choosing the size of the test sieve (including the diameter of the sieve frame, the sieve hole size and the number of sieve layers) is a key link in ensuring the accuracy and efficiency of material screening. Choosing the size of the test sieve requires comprehensive consideration of factors such as screening purpose, material characteristics, industry standards and equipment performance. The following are specific selection points and methods:

1. Understand sample characteristics

Material characteristics are mainly analyzed from the third aspect to determine the particle size range, material physical properties and material handling capacity.

If there are oversized particles in the material, a large-aperture sieve should be used for primary screening to avoid clogging. According to the particle size range required for screening, select a group of test sieves with geometric series (such as 2 times), such as 16mm, 8mm, 4mm, 2mm, etc.

For hard particles (such as ore), choose a wear-resistant material (such as stainless steel), and the shape of the sieve holes can be round or square. Flaky or needle-shaped particles (such as shale): The screening efficiency of square sieve holes is higher than that of round ones, because square holes are more sensitive to the passing rate of non-spherical particles. Wet or sticky materials (such as clay, wet sand) are easy to clog the sieve holes. It is necessary to choose a large-aperture sieve or a vibration device, or a woven mesh screen (with a large mesh spacing and less likely to get stuck).

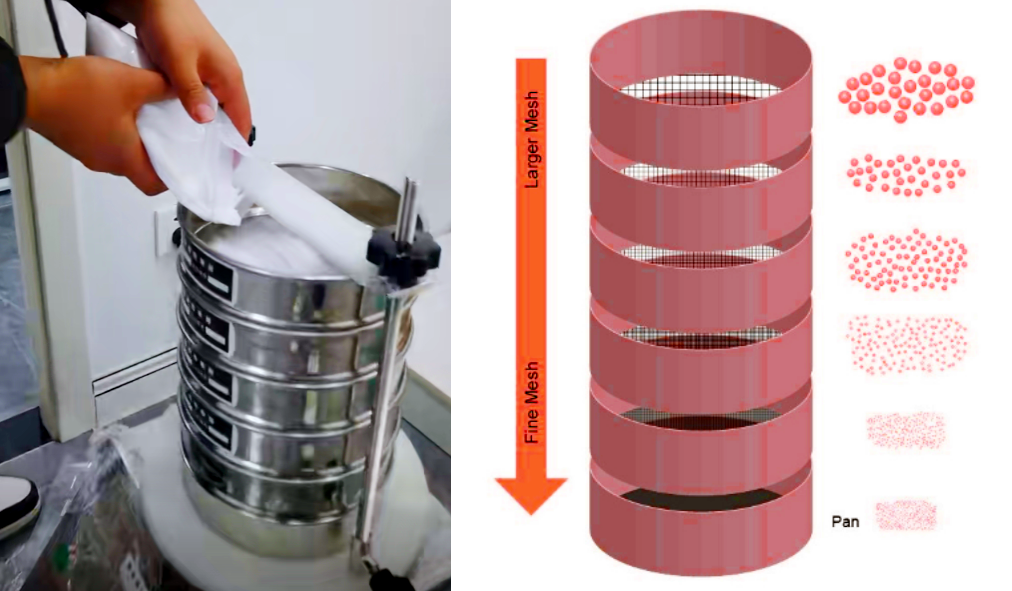

When the processing volume is large: choose a multi-layer sieve (such as 3 to 7 layers) to improve the screening efficiency; when the processing volume is small, a single-layer sieve or a small test sieve can be used.

2. Related selection of sieves

① Select the sieve hole size according to the particle size of the material

This is the primary basis for selecting a test sieve. The sieve hole size of the test sieve should be matched according to the particle size distribution range of the material to be screened. Common matching principles:

|

Material particle size range (mm) |

Recommended sieve size (mm) |

|

> 10 |

Coarse sieve (above 10mm) |

|

2~10 |

Medium sieve (2mm~10mm) |

|

0.075~2 |

Fine sieve (standard test sieve) |

|

< 0.075 |

Ultrafine sieve (metal mesh sieve or micro-porous sieve can be used) |

If it is a particle grading test, multiple sieve apertures covering this range should be selected (for example, 4.75mm, 2.36mm, 1.18mm, 0.6mm, etc.); if it is a precision analysis, a metal woven mesh or an electroformed mesh with a small error should be selected, and the particle size matching is more stringent.

② Determine the size and material of the sieve frame

Common test size diameters are 75mm, 100mm, 200mm, 300mm, etc. The laboratory commonly uses a 200mm diameter, which is suitable for most particle size analysis; industrial use may require a larger diameter. The standard sieve frame height is 50mm, and the half-height is 25mm. Choose a half-height sieve when the sample volume is small. Select the number of sieve layers according to the particle size range to be screened. Usually 5-8 layers of sieves can cover most needs. Φ200mm and Φ300mm are commonly used in laboratories. If the sample volume is large or the error needs to be reduced, a larger diameter sieve frame should be selected.

|

Sieve frame diameter (mm) |

Applicable scope |

|

75 |

Ultra-micro sample analysis |

|

100 |

Small batch experiment, scientific research sample analysis |

|

200 (common) |

Conventional particle size analysis, the most widely used |

|

300 |

Large batch screening, metallurgy and building materials and other industries |

|

400 |

Ultra-large sample volume or industrial primary screening purposes |

Stainless steel woven mesh is wear-resistant and corrosion-resistant, suitable for conventional particulate matter; brass mesh is suitable for powders that do not react with copper; electroformed mesh is suitable for high-precision, microparticle samples.

③ Determine the number of sieve layers and matching order

Generally, it is used in a coarse to fine order. It is recommended to use 5 to 8 layers of sieves for screening particle size analysis.

For example: for quartz sand particle size detection, you can choose 2mm, 1mm, 0.5mm, 0.25mm, 0.125mm, 0.075mm and other levels.

ASTM standard for test sieves

The sieve hole size in ASTM E11 is close to the international standard ISO3310-1, and mainly uses imperial units (inches and mm are marked in parallel). Commonly used standard sieve holes are:

|

Sieve number (U.S. No.) |

Sieve size (mm) |

Sieve size (inch) |

|

4 |

4.75 |

0.187 |

|

10 |

2.00 |

0.0787 |

|

20 |

0.850 |

0.0331 |

|

40 |

0.425 |

0.0165 |

|

60 |

0.250 |

0.0098 |

|

100 |

0.150 |

0.0059 |

|

200 |

0.075 |

0.0029 |

|

325 |

0.045 |

0.0017 |

Test sieve mesh number and aperture comparison table

|

Number |

mesh (mm) |

Number |

mesh (mm) |

Number |

mesh (mm) |

Number |

mesh (mm) |

|

2 |

13 |

26 |

0.71 |

90 |

0.16 |

260 |

0.06 |

|

3 |

6.5 |

28 |

0.63 |

100 |

0.154 |

2 80 |

0.055 |

|

4 |

5 |

30 |

0.6 |

110 |

0.14 |

300 |

0.054 |

|

5 |

4 |

32 |

0.55 |

115 |

0.13 |

320 |

0.048 |

|

6 |

3.2 |

36 |

0.5 |

120 |

0.125 |

325 |

0.045 |

|

7 |

2.8 |

40 |

0.45 |

130 |

0.111 |

35 0 |

0.041 |

|

8 |

2.5 |

45 |

0.4 |

140 |

0.105 |

360 |

0.4 |

|

9 |

2.2 |

50 |

0.355 |

150 |

0.1 |

400 |

0.0385 |

|

10 |

2 |

55 |

0.315 |

160 |

0.098 |

500 |

0.03 |

|

12 |

1.6 |

60 |

0.3 |

180 |

0.09 |

|

|

|

14 |

1.43 |

65 |

0.25 |

190 |

0.08 |

|

|

|

16 |

1.25 |

70 |

0.22 |

200 |

0.075 |

|

|

|

18 |

1 |

75 |

0.2 |

220 |

0.07 |

|

|

|

20 |

0.9 |

80 |

0.18 |

240 |

0.065 |

|

|

|

24 |

0.8 |

85 |

0.17 |

250 |

0.063 |

|

|

|

Specifications of stainless steel sample sieves. If you need special specifications, please contact online customer service for consultation. |

|||||||

Through the above steps, you can more systematically select the test sieve size that suits your test needs. If conditions permit, you can conduct a preliminary experiment to verify the suitability of the selected sieve by screening a small amount of samples. In short, choosing the right test sieve size is a comprehensive consideration process, involving multiple factors such as sample characteristics, screening purpose, and industry standards.