motorized vibrating soil sieve shaker machine

Tuesday June-10 2025 17:50:29

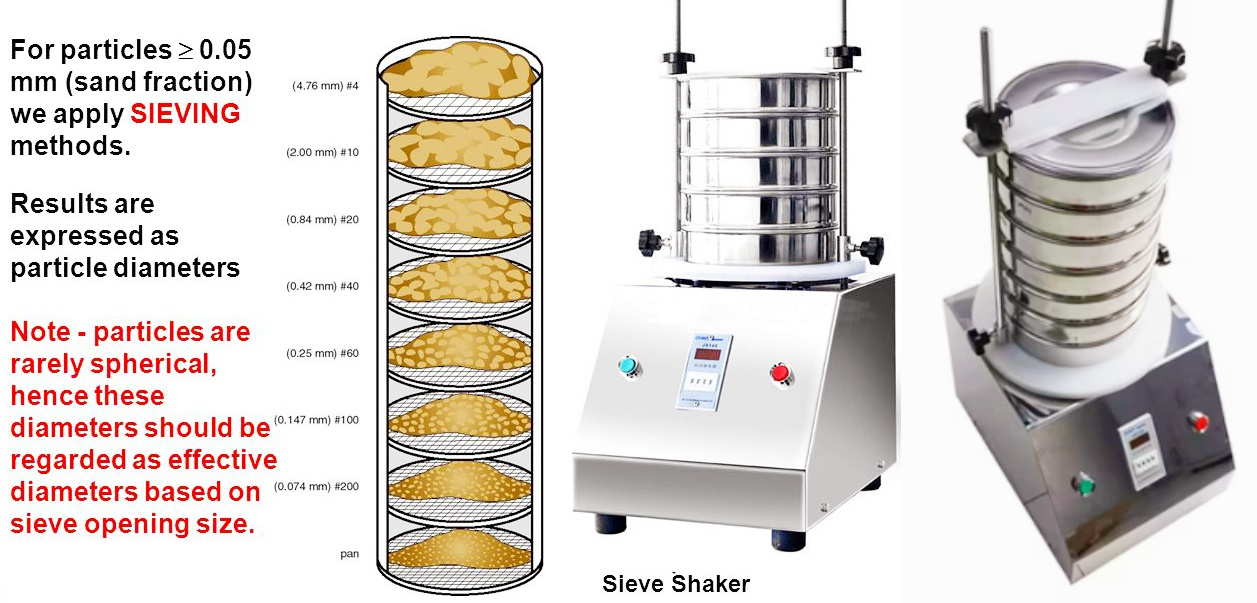

The motorized vibrating soil sieve shaker machine is a special equipment for soil particle size analysis. It drives multiple layers of sieves through a vibration motor to classify and separate soil samples according to particle size. Its main features include an efficient vibration system (adjustable frequency and amplitude), a multi-layer sieve design (aperture from 20µm to 63mm), and the flexibility to support dry and wet sieving. Configure multiple layers of sieves according to needs, from coarse screening to fine screening, to effectively separate the soil into 2-3 or more layers of different particle sizes, such as removing large stones and plant roots, while separating coarse sand, fine sand and even fine soil.

Differences between motorized vibrating soil sieve shaker machine and electromagnetic sieving machine

The motorized vibrating soil sieve shaker machine is a soil screening device driven by a mechanical vibration motor, which is widely used for soil particle size analysis. Its core feature is to generate high-frequency vibration through eccentric weights or vibration motors, so that soil samples can be graded according to particle size on multi-layer sieves.

The sieve aperture range is wide (20µm to 63mm), supporting dry screening and wet screening to adapt to different soil types. The equipment is usually equipped with 3-8 layers of sieves, with adjustable amplitude and frequency, high screening efficiency, and suitable for laboratory and field use.

The electromagnetic sieving machine adopts electromagnetic drive technology to generate high-frequency micro-vibration through electromagnetic pulses for precise screening of fine soil samples. Compared with motorized vibrating screens, its vibration is gentler and more precise, and the amplitude and intermittent time can be precisely adjusted by digital control, which is particularly suitable for the analysis of micron-sized particles (as small as 5µm).

The equipment is usually equipped with high-precision screens (up to 8-10 layers), and the screening process is low in noise and dust, which is suitable for the high-precision needs of laboratories. The disadvantages are small processing capacity, high equipment cost, and low screening efficiency for sticky or wet soils.

How does a motorized vibrating soil sieve shaker machine work

The equipment is equipped with a vibration motor or other mechanical device inside to produce strong vibration. This vibration can be controlled by adjusting the frequency and amplitude to adapt to materials of different particle sizes. The screen is usually set at a certain inclination angle, and the combination of gravity and vibration is used to cause the particles to move along the surface of the screen. Larger particles are screened to the upper layer due to gravity, while smaller particles fall into the lower layer through the screen pores.

Motorized vibrating soil sieve shaker machines are usually equipped with multiple layers of screens, which can achieve graded screening. The screens of different layers have different apertures, which can effectively classify materials into multiple levels such as coarse, medium and fine. After screening, the materials are collected in different containers for subsequent analysis and processing. The design of the equipment ensures the efficiency and stability of the screening process.

What are the disadvantages of the motorized vibrating soil sieve shaker machine?

Although the motorized vibrating soil sieve shaker machine has the advantages of high efficiency and convenience in soil particle grading tests, it also has some disadvantages and limitations that cannot be ignored in actual use.

① Limited efficiency in screening fine particles: small particles with a particle size of less than 0.075mm (such as silt, clay, etc.) are not easy to pass through the sieve due to surface tension, charge adsorption or agglomeration. It is easy to cause test errors and is not suitable for high-precision fine particle grading analysis.

② Particle crushing caused by vibration: Some soils are prone to crushing or deformation under high-frequency vibration. It may change the original particle size composition of the particles and affect the accuracy of the particle grading test. For example, weathered rocks and soft muddy soil samples are broken into fine particles after screening, resulting in a high content of the sieve.

③The equipment is small and the processing capacity is limited: the motorized vibrating soil sieve shaker machine is usually a small laboratory equipment, and the single processing sample volume is small. It is not suitable for screening a large number of samples or large-scale soil screening operations on site. If a large processing volume screening task is required, an industrial vibrating screen must be used.

④Poor adaptability to non-dry samples: the motorized vibrating soil sieve shaker machine is mostly used for dry screening and is not suitable for screening wet soil with a high moisture content. The sample must be dried first, which increases the test steps and time. If necessary, it must be used in conjunction with drying equipment, or wet screening equipment must be used.

Relevant specifications of the motorized vibration soil sieve shaker machine

|

Specifications |

Typical range/description |

Specifications |

Typical range/description |

|

Screen diameter |

200mm, 300mm, 400mm and other specifications |

Number of screen layers |

2 to 7 layers |

|

Vibration frequency |

1400~3000 times/minute |

Vibration amplitude |

1~5 mm |

|

Motor power |

0.18 kW~0.55 kW |

Processing capacity |

10~50kg/time (depending on the number of screen layers and material properties) |

|

Timing range |

0~60 minutes adjustable |

Power supply requirements |

220V/50Hz single-phase power supply |

|

Weight |

about 30~80 kg (depending on the model) |

Dimensions |

about 600×600×700 mm (length×width×height) |

|

Applicable material particle size |

0.075 mm or more particles |

||

What is the purpose of the mobile vibration soil sieve shaker machine

The mobile vibration soil sieve shaker machine is mainly used for screening and grading analysis of soil particles. It is a commonly used laboratory equipment in geological exploration, civil engineering, environmental science and agricultural research.

In geological exploration, it helps engineers accurately determine the particle size composition of the soil, evaluate the bearing capacity of the foundation and the permeability of groundwater, and provide a scientific basis for building design; before civil engineering construction, screening soil samples can detect soil types and guide construction plans and material selection; in the field of environmental science, screening and analyzing soil particle distribution, assessing soil pollution and the effects of improvement measures; agricultural research uses this equipment to analyze soil structure and optimize farming and planting plans.

This equipment is suitable for laboratory grading tests of soil samples of different particle sizes such as fine sand, silt, and clay. Common application scenarios include mine sampling and analysis, road base soil testing, construction site soil testing, and research on soil physical properties in scientific research institutes. The mobile vibration soil sieve shaker machine has become an important tool for soil particle separation and particle composition research with its high efficiency, accuracy and convenient operation.

The motorized vibrating soil sieve shaker machine is a kind of experimental equipment commonly used in the fields of geology, construction, geotechnical engineering, etc. It is mainly used for particle classification of soil samples. Its working principle is based on vibration screening. The motor drives the sieve body to vibrate with a certain frequency and amplitude, so that particles of different sizes are separated according to the size of the sieve mesh. It can flexibly set different screening levels according to actual needs, which can not only meet the fine requirements of soil particles in agricultural soil improvement, but also is suitable for the screening of sand and gravel particle size in the laboratory.