The difference between square swing screen and linear vibrating screen

Friday July-11 2025 10:05:06

Square swing screen and linear vibrating screen are two commonly used equipment in industrial screening. They have significant differences in structure, working principle, screening effect, applicable materials and application fields. Understanding these differences can help you choose the screening equipment that best suits your needs.

Differences in structure and working principle

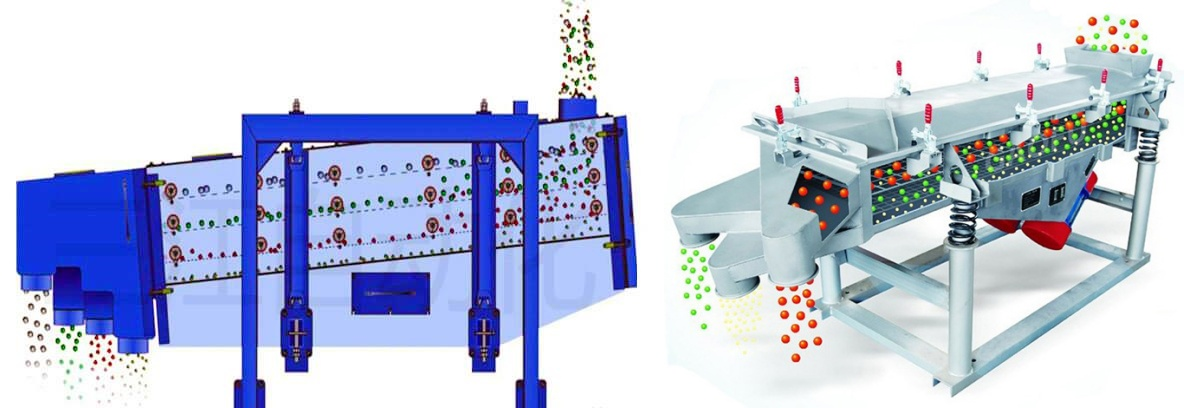

The square swing screen contains one or more inclined screen layers, and an eccentric drive device drives the entire screen body to move.

Working principle: Simulating the manual screening action, the screen body performs reciprocating nonlinear motion in the horizontal direction (usually approximately circular or elliptical motion), and at the same time, with the inclination angle of the screen surface itself, the material forms a spiral forward motion on the screen surface. This movement allows the material to stay on the screen for a long time, and is constantly dispersed, layered and passes through the screen holes.

Linear vibrating screens are usually composed of screen boxes, vibration motors (or exciters), vibration reduction devices and support frames.

Working principle: The exciting force generated by the vibration motor is used to make the screen body vibrate back and forth at a high frequency along a fixed straight line. Under the action of the vibration force, the material is thrown up on the screen surface and jumps forward to achieve classification through the screen holes.

Difference in screening effect

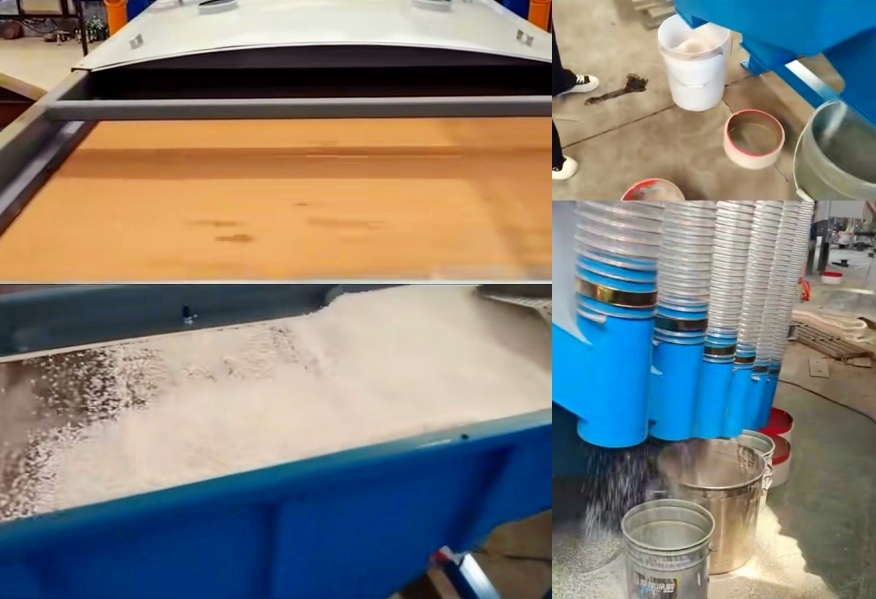

The square swing screen performs well in screening effect, especially for materials with high screening accuracy requirements, easy to block holes, and difficult to screen. Its unique swinging motion mode allows the material to stay on the screen for a longer time, so that it can be fully dispersed and effectively layered, thereby greatly improving the screening efficiency and accuracy, and effectively reducing the clogging of the screen.

The screening effect of the linear vibrating screen is mainly reflected in its fast screening speed and large processing capacity. It has a good screening effect for materials with larger particles, better fluidity and relatively less demanding precision requirements.

|

Comparison dimension |

square swing screen |

linear vibration screen |

|

Screening accuracy |

high, suitable for fine powder and high mesh screening, the screening particle size can reach more than 400 mesh |

medium, suitable for coarse to medium particle size materials, usually the screening particle size does not exceed 200 mesh |

|

Screening efficiency |

accuracy first, the processing volume per unit time is not as good as the linear screen |

large processing volume and high efficiency, but it is more advantageous when the screening accuracy requirement is not high |

|

Material damage degree |

low, gentle movement, suitable for brittle, fragile or high particle integrity requirements |

strong vibration force, which may cause material breakage, not suitable for the screening process that requires the integrity of particles |

|

Net blocking |

reducing the probability of network blocking through slow swing and bouncing ball device design, suitable for sticky fine powder |

sticky materials are easy to block the network, and there are limitations on wet powder and fine powder screening |

Differences in the application field of applicable materials

Square swing screen is mainly suitable for fine powder, ultrafine powder, easy to agglomerate materials, lightweight materials and scenes requiring multi-level classification. It is widely used in the following fields:

Food industry: starch, flour, sugar, milk powder, coffee powder, etc.

Chemical industry: fertilizer, resin powder, dye, pigment, PVC powder, plastic particles, etc.

Pharmaceutical industry: Chinese and Western medicine powder, tablet particles, etc.

Minerals and metallurgy: quartz sand, abrasives, ceramic raw materials, non-metallic minerals and other materials with high precision requirements.

Linear vibrating screen is mainly used for screening large and medium-sized dry or wet materials. It has a large processing capacity and stable operation. It is widely used in the following fields:

Mining: coal, ore, crushed stone, sand and gravel, etc.

Construction: sand and gravel, cement, concrete aggregate, etc.

Metallurgy: coke, sintered ore, pelletized ore, etc.

Coal: raw coal, washed coal, etc.

How to choose square swing screen and linear vibrating screen?

For fine powder, easy to agglomerate, sticky or materials with strict requirements on particle size distribution, square swing screen is a better choice; for materials with large particles, good fluidity, moderate water content and high screening speed requirements, linear vibrating screen will be more suitable. If you need to obtain high-precision, high-purity products and want to reduce clogging, choose a square swing screen; if you mainly pursue large processing capacity and faster screening speed, and have relatively loose requirements for accuracy, a linear vibrating screen can meet your needs.

Taking the above factors into consideration, when choosing the right screening equipment, you need to decide based on material characteristics, production requirements and screening accuracy. If you are still unsure, you can consult a professional screening equipment supplier, and Dahan will provide more detailed suggestions and solutions based on your specific situation.