Why use ultrasonic test sieve to screen electric powder?

Saturday June-28 2025 13:35:49

Because electric powder particles are extremely fine, usually with a particle size of more than 200 mesh (about 75 microns) or even hundreds of meshes, and have strong agglomeration, electrostatic adsorption and high density, ordinary mechanical vibration screens are difficult to effectively separate and screen, and are prone to screen clogging and low screening efficiency.

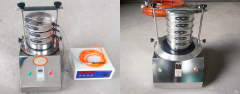

The electric powder ultrasonic test sieve is equipped with a high-frequency ultrasonic generator on the basis of the traditional test sieve, so that the powder is suspended on the screen, fully breaking the agglomeration and avoiding screen clogging, thereby significantly improving the screening efficiency and accuracy. This equipment is suitable for multi-layer screening, and can generally be equipped with 2 to 4 layers of screens to achieve graded screening of different particle sizes.

The difference between ultrasonic test sieve and standard test sieve in screening electro-powder

The difference between ultrasonic test sieve and standard test sieve in screening electro-powder is mainly reflected in screening efficiency, screening accuracy, applicable material fineness and anti-blocking effect.

The standard test sieve relies on mechanical vibration (such as circular vibration or linear vibration) to drive the screen vibration to allow the material to pass through the sieve hole. The vibration frequency and amplitude are fixed, and the movement of the material on the screen is relatively rough. The ultrasonic test sieve is based on the standard sieve machine, with high-frequency ultrasonic vibration (usually 30~40kHz) added to generate tiny high-frequency vibration energy to help loosen the powder and effectively clean the sieve hole.

In terms of screening efficiency:

The standard sieve has a better screening effect on materials with coarse particle size and good fluidity, but for fine powder, especially electro-powder above 200 mesh (≤75 microns), the screening efficiency decreases and it is easy to block the net. The ultrasonic screen uses ultrasonic vibration to break the powder agglomeration, improve the ability of materials to pass through the sieve holes, and greatly improve the efficiency of fine powder screening, especially for ultrafine electric powder.

In terms of screening accuracy:

The screening accuracy of the standard screen is limited by the vibration mode, fine particles are easy to gather, and the screening results may have large deviations. The ultrasonic vibration of the ultrasonic screen allows the material to pass through the screen in a "suspended" state, and the particle separation is more thorough, and the particle size control is more accurate.

In terms of anti-blocking ability:

The standard screen makes it easy for fine powder to adhere to the screen, and the screen holes are seriously blocked, requiring frequent cleaning, affecting work efficiency and screen life. The ultrasonic screen continuously cleans the screen holes through ultrasonic vibration, reduces blockage, reduces the frequency of manual maintenance, and extends the service life of the screen.

In terms of the range of applicable materials:

Standard screen: suitable for medium and coarse particle powders and electric powder materials with good fluidity.

Ultrasonic screen: suitable for ultrafine powders, serious agglomeration, high static electricity and high-density electric powder materials, such as tungsten powder, titanium powder, copper powder, etc.

Reasons for using ultrasonic test sieves to screen battery powder:

There are several main reasons for using ultrasonic test sieves to screen battery powder (usually refers to electrolytic powder, metal powder or other fine particle materials):

Improve screening efficiency: Battery powder particles are usually very fine and are prone to clogging (screen mesh is blocked) during traditional screening. Ultrasonic test sieves use high-frequency vibration (usually in the range of 20-40kHz) to make the screen vibrate slightly, effectively preventing particles from adhering and clogging, and improving screening efficiency.

Handling fine particles: The particle size of battery powder is often in the micron level, and traditional vibrating screens may have difficulty in effectively separating such fine particles. Ultrasonic sieves can better disperse and separate fine particles through the mechanical wave action of ultrasound, ensuring a more accurate particle size distribution.

Reducing agglomeration: The high-frequency vibration of ultrasound can instantly destroy the agglomeration force between powder particles, dispersing the agglomerates into individual particles, so that they pass through the screen. For example, for nano-scale barium titanate powder, ordinary vibrating screens may cause 30% of fine powder to fail to pass through the screen due to agglomeration, while ultrasonic screening can increase the pass rate to more than 95%.

Eliminate static adsorption: The static electricity generated by the powder will cause the particles to adsorb on the screen to form a "screen paste" phenomenon. Ultrasonic vibration causes the particles to jump on the screen at a high frequency through mechanical movement, reducing the probability of adsorption. For example, when screening lithium battery positive electrode materials (such as lithium iron phosphate), the ultrasonic screen can reduce the screen blockage rate by 80%, without frequent shutdown and cleaning.

The total ultrasonic test sieve is particularly suitable for screening electric powder, easy to clog and agglomerate materials such as powder, which can significantly improve the screening efficiency, accuracy and equipment durability, and meet high-standard industrial and experimental needs.