What is a laboratory round sieve used for?

Friday June-27 2025 14:06:30

Laboratory round sieves are a standard sieving tool for particle size analysis and classification of granular and powdered materials. They are widely used in scientific research, quality inspection, teaching, material research and other fields. The core function of laboratory round sieves is to achieve quantitative and qualitative classification and particle size detection of granular materials, helping researchers and quality inspectors to accurately grasp the particle distribution characteristics of materials, thereby guiding production process adjustments or scientific research analysis.

The sieves of laboratory round sieves have different specifications, which are mainly distinguished by the size and diameter of the sieve holes. The diameters are 100mm, 200mm, 300mm, etc., and 75mm and 400mm can also be customized. According to the sieve manufacturing process, it can be divided into three categories: wire woven mesh test sieve, metal perforated plate test sieve and electroforming test sieve.

①Wire mesh test sieve: The sieve holes are square, affordable, lightweight and durable. The sizes include 200mm, 75mm, 300mm, and the sieve hole sizes range from 0.02mm to 2.36mm.

②Metal perforated plate test sieve: The sieve holes can be directly punched into square or round shapes, suitable for materials with high density, large impact and irregular shapes. The sizes are 200mm and 300mm, and the sieve hole sizes range from 1mm to 125mm.

③Electroforming test sieve: Produced by electrochemical methods, it has the highest accuracy and is suitable for high-precision laboratories. The sizes are 75mm and 200mm, and the sieve hole sizes range from 5 microns to 500 microns.

What is the purpose of laboratory round sieves?

Particle size analysis: Laboratory round sieves are often used to analyze the proportion of particles of different particle sizes in materials and determine the particle size composition of materials. It is suitable for particle grading analysis of building materials such as soil, sand, and cement; particle size control of metal powders and chemical raw materials; particle size consistency detection of food powders (such as flour and milk powder); particle screening and quality control in pharmaceutical raw materials.

Sample preparation: In some tests, the material needs to be pretreated to make its particle size meet the requirements of subsequent experiments. The laboratory round sieve can be used to screen mixed particles into samples of different particle sizes; remove impurities or overly coarse/fine particles to improve the representativeness and consistency of the sample.

Standard screening test: The laboratory round sieve can be used with a slap screen or a vibrating screen to conduct screening tests that comply with ISO, ASTM, GB and other standards to ensure that the product meets the industry particle size specifications. In colleges and universities and research institutes, laboratory round sieves are often used to teach screening theory and particle size distribution analysis; material classification and particle characteristics research; soil classification, mineral testing and other scientific research experiments.

Application of laboratory round sieve

As the core tool for particle size analysis and material classification, the laboratory round sieve undertakes key detection and production auxiliary functions in many fields, and its application scenarios cover multiple links from scientific research analysis to industrial production.

In the field of geology and mineral research: Soil particles are divided into sand (2-0.05mm), powder (0.05-0.002mm) and clay (<0.002mm) according to particle size through a circular sieve, and the soil texture (such as sand, loam, clay) is evaluated based on the proportion of each component. Ore particles are screened before mineral processing to determine the particle size range suitable for crushing or grinding; after mineral processing, the particle size distribution of concentrates and tailings is tested to evaluate the mineral processing efficiency.

In the field of chemical engineering and materials science: Catalyst particles (such as molecular sieves, precious metal catalysts) are screened to ensure their particle size uniformity to optimize the efficiency of catalytic reactions; the particle size of adsorbent materials such as activated carbon and silica gel is tested to study the relationship between their specific surface area and adsorption performance. Coating powders (such as electrostatic spray powders) are screened to avoid uneven coating caused by large particles; the particle size of pigment particles (such as titanium dioxide and iron oxide) is tested to control coloring power and dispersibility.

Food and pharmaceutical industry: sieve flour, starch, powdered sugar and other raw materials to control the coarseness of the product (e.g. high-gluten flour requires coarser particles); detect the particle size of chopped nuts and coffee powder (e.g. instant coffee particles are too fine and easy to clump).

Pharmaceutical preparation and quality inspection: sieve drug powders (e.g. tablet raw materials, capsule fillers) to ensure that the particle size meets the dissolution requirements; detect the particle size of Chinese herbal medicine pieces and extract particles to control the release rate of drug efficacy.

Scientific research and teaching experimental scenarios: In nanomaterial research, nanoparticles (such as TiO₂, graphene powder) are sieved through high-precision circular sieves to study the relationship between particle size and photocatalytic and electrical properties. As a basic experimental tool, it helps students understand concepts such as "screening principle" and "particle size distribution" and master the operation methods of material classification.

Application case display of laboratory circular sieve

Case 1: Fineness analysis in cement laboratory

In a building materials laboratory, in order to evaluate the quality of different batches of cement, a laboratory circular sieve (standard sieve hole 45μm) was used for fineness test. The operator pours a certain amount of cement sample into the round sieve, and after running the slap screen for 15 minutes, weighs the residue on the sieve. By calculating the percentage of sieve residue, it is determined whether the cement meets the requirements of GB/T 1345-2005 Cement Fineness Test Method, thereby controlling the cement strength grade.

Case 2: Soil Particle Classification in Agronomic Research

In an agricultural research institution, a group of researchers used a φ200mm laboratory round sieve and multi-level sieves ranging from 2mm to 0.075mm to analyze the particle composition of soil samples collected from different plots. The mass after each level of screening is used to draw a particle size distribution curve, and then analyze the soil type and farming suitability of each plot, providing a basis for fertilization and irrigation plans.

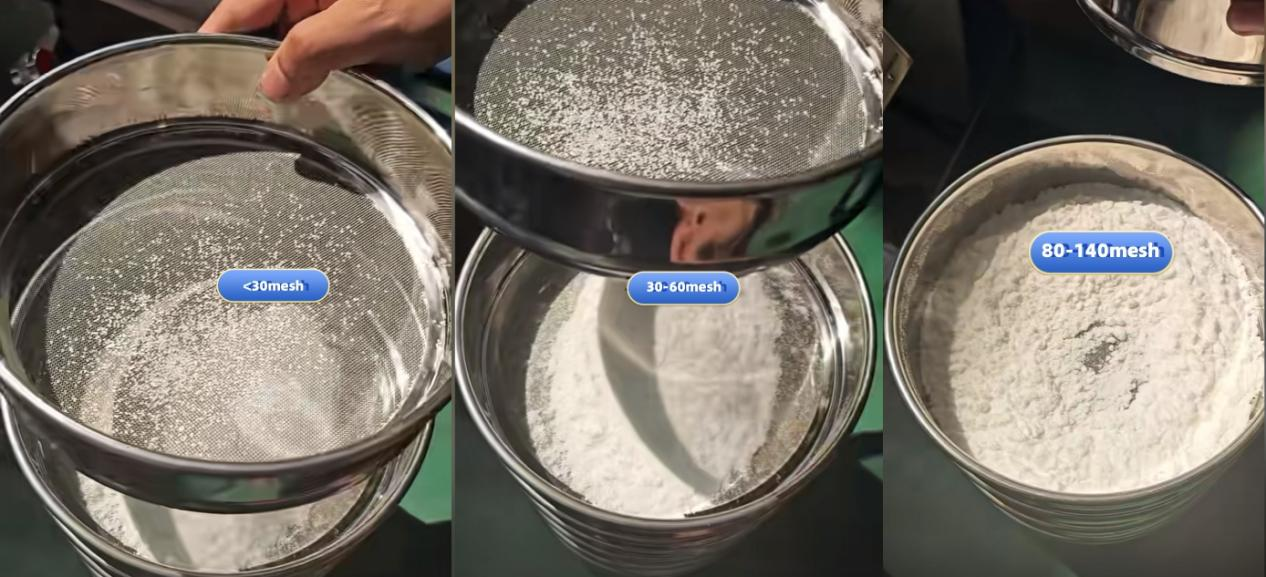

Case 3: Classification test of a metal powder production enterprise

In the laboratory of a metal 3D printing material company, a laboratory round sieve (particle size ranges from 300μm to 45μm) is used to perform multi-level screening of atomized metal powder. The powders after screening at various levels are used in different additive manufacturing processes to ensure that each product uses raw materials with the most suitable particle size range, improving the density and strength of the printed products.

Laboratory round sieves are mainly used for particle separation, grading, filtration and particle size analysis due to their efficient screening performance, wide application fields and easy operation. They have become an indispensable and important equipment for laboratories, quality inspection rooms, food, chemical, pharmaceutical, agricultural, scientific research and other industries.