What is a bucket elevator for pet food?

Thursday May-29 2025 15:13:27

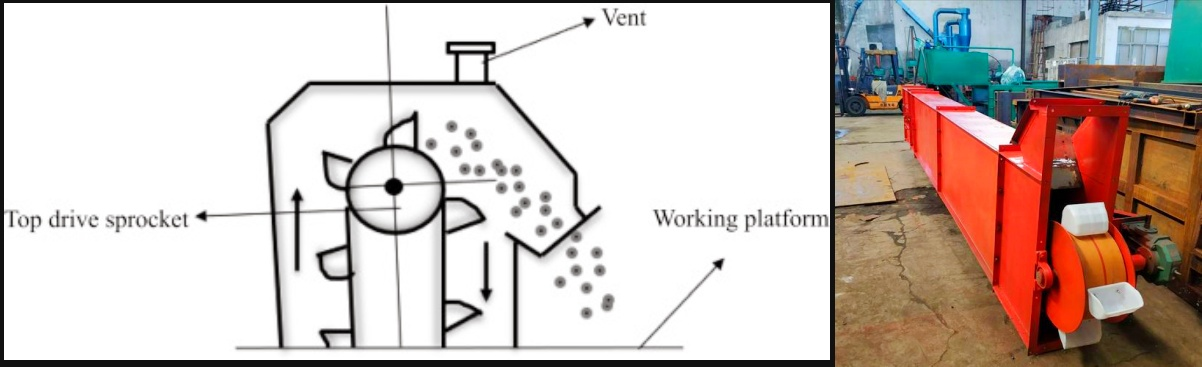

Bucket elevator for pet food is a vertical continuous conveying equipment designed for granular, puffed or small block pet food. In view of the characteristics of pet food being fragile (such as puffed food), easy to generate dust, and extremely high requirements for hygiene and safety, a series of hoppers fixed on a circular traction belt (or chain) are used. After digging or receiving materials at the bottom, they are vertically lifted to the top, and then the materials are gently dumped to the discharge port by centrifugal or gravity.

This conveying method is efficient and occupies a small area, and is particularly suitable for multi-story plant layouts. Its fully enclosed casing effectively isolates dust from escaping and external pollution, meeting strict food hygiene standards; at the same time, by using food-grade stainless steel or engineering plastic hoppers, optimizing hopper shapes (such as shallow hoppers or deep hoppers) and operating speeds, it can minimize the breakage and wear of food during the lifting process, ensuring the integrity of the product. Therefore, pet food bucket elevators are key equipment for achieving efficient, hygienic, and low-damage vertical transportation, and are widely used in material lifting and transportation in production links from raw material processing, mixing, puffing/granulation, cooling and drying, seasoning spraying to finished product packaging and warehousing.

Scope of application of pet food bucket elevators

Pet food bucket elevators are suitable for the full chain of pet food production, processing, and warehousing, and their scope of application covers three dimensions: material type, production link, and functional requirements.

Granular materials: round and oblate particles (diameter 2-12mm) such as puffed grains and baked grains, such as adult cat food and dog food staples.

Powdered/fine granular materials: bone meal, fish meal, vitamin powder, wheat flour and other additives; seasoning powder, coating powder and other fine powder materials that need to be evenly mixed.

Block/flaky materials: meat blocks, vegetable blocks (after pretreatment), tablets (such as tooth-cleaning tablets), low-impact conveying is required.

How does the bucket elevator for pet food work?

The bucket elevator for pet food is a mechanical equipment specially used for vertical or inclined conveying of pet food raw materials (such as grains, meat and bone meal, vitamin premixes, etc.) and finished products. It is widely used in pet feed processing production lines. Its core function is to efficiently lift materials from low to high through a closed hopper circulation system to meet the process requirements in the production process.

The pet food enters the bottom of the casing from the feed inlet, and the hopper is inserted into the material when it runs down to the bottom with the traction member. Through the operation of the elevator (the chain or belt drives the hopper to move upward), the pet food is scooped up and lifted to the top with the hopper. When the hopper reaches the discharge port, the material is discharged from the hopper due to centrifugal force or gravity and transported to the next process through the discharge port.

Why use bucket elevators in the pet food industry?

Pet food production involves various forms such as granular materials (such as puffed grains), powdered materials (such as bone meal, vitamin additives), and block materials (such as meat blocks). Bucket elevators can solve the transportation problems of various materials in a targeted manner by configuring different types of hoppers (such as deep buckets, shallow buckets, and arc buckets): deep buckets are suitable for puffed grains with large particles and good fluidity, shallow buckets are suitable for powdered materials that are easy to adhere, and arc buckets can reduce the wear of block materials, ensuring that materials at different stages can be efficiently transported.

Compared with traditional horizontal conveying equipment, bucket elevators can achieve vertical lifting in a limited space, saving floor space, and are especially suitable for the three-dimensional production line layout of multi-story factories. It has high conveying efficiency (can convey several tons to tens of tons of materials per hour), and by controlling the hopper running speed (such as centrifugal high-speed unloading, gravity-type low-speed steady flow), it can accurately match the rhythm of the production line to avoid material accumulation or breakage. It is especially suitable for impact-sensitive products such as crispy granular grains and fragile snacks.

Technical specifications of bucket elevator for pet food

|

Model |

Max feed size(mm) |

Capacity(T/H) |

Lifting speed(m/s) |

Belt width(mm) |

Lifting height(m) |

|

TD160 |

25 |

5.4-16 |

1.4 |

200 |

<40 |

|

TD250 |

35 |

12-35 |

1.6 |

300 |

|

|

TD315 |

45 |

17-40 |

1.6 |

400 |

|

|

TD400 |

55 |

24-66 |

1.8 |

500 |

|

|

TD500 |

60 |

38-92 |

1.8 |

600 |

|

|

TD600 |

70 |

85-142 |

2 |

700 |

What can bucket elevator for pet food be used for?

Pet food bucket elevator plays a key role in the entire process of pet food production. In the raw material processing stage, grains, meat powder, vitamin additives, etc. can be lifted vertically from the storage bin to the grinder to complete the preliminary processing; or conveyed to the mixer to fully mix the various raw materials. In the semi-finished product processing stage, it can lift the puffed pet food particles from the puffer to the dryer, accurately control the conveying volume, and avoid material accumulation; it can also convey the dried semi-finished products to the cooler to ensure that the materials are quickly cooled.

In the finished product processing stage, the bucket elevator can lift the cooled pet food to the packaging station, connect with the automatic weighing and packaging equipment to achieve automatic packaging; it can also convey the finished products from the ground to the upper layer of the storage shelf for efficient storage and management. For powdered or small-granular pet snack raw materials, the combination of shallow bucket and low-speed operation can be smoothly conveyed to the molding equipment, reducing material spillage and loss, and ensuring production efficiency and product quality.

The total bucket elevator for pet food is suitable for various scenarios where bulk, granular or small-block pet food needs to be lifted vertically. It is an important equipment for realizing the automation of pet food production and packaging and improving efficiency. By properly selecting and maintaining bucket elevator for pet foods, the automation level and production efficiency of the pet food production line can be effectively improved, and product quality and hygiene safety can be guaranteed.