What is orange juice filter screen

Saturday June-21 2025 18:05:49

The orange juice filter screen is a solid-liquid separation device designed for the characteristics of orange juice. Its core function is to remove solid impurities (such as pulp fiber, pomace, seed crumbs, etc.) in orange juice by physical interception, while retaining the soluble components in the juice (such as sugar, vitamins, organic acids, etc.). Its essence is to achieve separation by using the difference between the aperture of the screen and the size of the impurity particles

What is the working principle of the orange juice filter screen

The working principle of the orange juice filter screen is mainly based on the physical separation method, and the solid matter (such as pulp, seeds and fiber, etc.) in the orange juice is separated from the liquid part by screens or filter materials with different apertures.

The motor generates an exciting force, which makes the screen vibrate at a high frequency. The orange juice spreads and flows rapidly on the screen surface. The liquid part passes through the screen and enters the lower discharge port. The solid impurities are blocked and discharged along the screen surface to the slag discharge port, realizing solid-liquid separation. Vibration is used to accelerate the liquid to penetrate the screen. The screens of different meshes can be replaced to adjust the filtration accuracy. The processing speed is fast and suitable for large-scale continuous operation. It is often used for coarse filtration and medium-precision filtration.

The difference between orange juice filter screen and horizontal centrifugal screen

The orange juice filter screen (vibrating type) is suitable for primary filtration, pulp control, seed removal and other operations of orange juice. It is cost-effective and suitable for small and medium-sized juice processing needs. The horizontal centrifugal screen is suitable for deep purification, efficient continuous filtration, industrial-grade mass production of orange juice, and more thorough filtration.

|

Comparison project |

orange juice filter |

horizontal centrifugal screen |

|

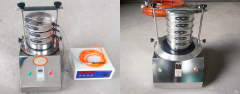

Image |

|

|

|

Working principle |

using motor vibration to push orange juice to spread on the screen surface and pass through the mesh |

using high-speed rotation of the screen drum to generate centrifugal force to separate liquid and solid |

|

Separation method |

material passes through the filter under the action of vibration |

liquid passes through the mesh under the action of centrifugal force, and impurities are thrown out |

|

Applicable materials |

fruit juice with less pulp or moderate concentration |

high pulp, high fiber or high viscosity orange juice |

|

Filtering accuracy |

changeable screen control (commonly used 30-200 mesh) |

fine, thorough slag removal, mesh size is generally above 100 mesh Top |

|

Processing capacity |

suitable for medium output, intermittent or batch processing |

continuous operation, suitable for large output continuous production line |

|

Is it easy to block the net |

easy to block the net due to pulp and fiber, need frequent cleaning |

not easy to block the net, automatic slag discharge |

Choice of mesh number of orange juice filter screen

Coarse filter (10-30 mesh): low mesh number, large mesh, can quickly filter out large pieces of pulp, core and other impurities, suitable for people who want to retain more pulp fiber and like thicker orange juice, fast filtering speed, can process a large amount of orange juice in a short time.

Medium filter (30-100 mesh): moderate mesh, can filter out most of the pulp particles visible to the naked eye, and can retain a certain amount of juice fiber, making the orange juice taste relatively delicate, while not losing the rich taste level, is a more commonly used choice.

Fine filter (100 mesh or more): The mesh is very small and can filter out extremely fine impurities to obtain almost completely clear orange juice. It is suitable for the pursuit of an extremely smooth taste or for situations where the appearance of orange juice is required to be high, such as for making high-end beverages or for commercial sales.

What can the filter screen be used for in the field of orange juice

The initial separation of juice and pomace in the juice production line;

The fruit particle filtration link in the supermarket freshly squeezed orange juice equipment;

The secondary purification treatment before canning orange juice;

The mixed filtration treatment of orange juice, carrot juice and apple juice in the food factory;

Application examples of orange juice filter screen

Home scene: Manual stainless steel filter screen to filter freshly squeezed orange juice, 500ml of juice can be filtered within 1 minute, there is no obvious pomace in the filtrate, but it may contain a small amount of pulp particles, suitable for direct drinking;

Small beverage shop: Use a small filter screen with vibration function, the processing capacity is about 20L/hour, the filtrate clarity is moderate, suitable "Suitable for making freshly squeezed orange juice drinks" (such as with ice cubes and syrup);

Food factory: Large rotary vibrating screen with multi-stage filtration (first coarse sieving and then fine sieving) can reduce the turbidity of orange juice to below 15NTU, meeting the initial clarification requirements of bottled juice, and then plate and frame filtration can be used for further purification.

The orange juice filter screen effectively separates solids and liquids through physical sieving to meet different taste and clarity requirements. In view of the high viscosity and pulp characteristics of orange juice, it is crucial to choose the right mesh size (60-100 mesh) and material (stainless steel is preferred). Coarse mesh screens are recommended for home use to retain the taste, and fine mesh screens can be used for commercial use to improve the appearance.